Stone veneer for outdoor kitchen: Durable, Stylish Choices

When building an outdoor kitchen, you are not just creating a place to cook—you are making a long-term investment in your property. That’s why using real stone veneer is the standard for a project that needs to perform reliably and maintain its appearance for decades.

Why Real Stone Veneer Is the Standard for Outdoor Kitchens

Unlike manufactured alternatives that can fade or degrade, real New England stone veneer brings a permanent color and authentic texture that sun, rain, and snow cannot diminish. It is the material of choice for high-performance outdoor projects where longevity and authentic craftsmanship are non-negotiable.

The success of any outdoor kitchen hinges on the materials chosen. The structure will be exposed to constant moisture, harsh UV rays, and—especially in New England—severe freeze-thaw cycles. Stoneyard’s natural thin stone veneer, sourced from regional quarries and fieldstone, is engineered to handle these conditions.

Each piece is 100% real stone, crafted at our Littleton, MA facility, and sawn to approximately one inch thick (with a range of ¾ to 1¼ inches). This provides the genuine, full-depth appearance of traditional masonry without the significant weight. This often eliminates the need for heavy-duty structural footings required for full-bed stone, reducing installation time and cost.

Built for Harsh Climates

Every Stoneyard product is Harsh Climate Approved (HCA), a critical specification for any outdoor build. This designation confirms the stone has low water absorption and high density, which prevents the cracking and spalling that destroys lesser materials over time.

This is where real natural stone veneer demonstrates a significant performance advantage over cement-based products like Eldorado Stone or Cultured Stone. With manufactured veneers, the color is a surface-level pigment. With real stone, the color and texture are integral to the material itself.

Natural New England stone veneer delivers multi-decade performance with minimal maintenance and no color fading. The character of real stone runs through the entire body, ensuring it develops a natural patina over the years instead of degrading.

The durability of natural stone is a key reason for its high demand in outdoor living spaces. This trend is driven by homeowners choosing durable, authentic materials like real stone veneer for residential and commercial projects.

Authenticity and Performance Combined

Choosing genuine stone veneer means your outdoor kitchen will not only perform for decades but will also carry the authentic look of New England’s building heritage. It’s a long-term investment that adds measurable value to your property. Sourced and Made in the USA, it reflects authentic craftsmanship.

For a deeper analysis, learn more about why natural thin veneer stone is best for exterior use in our technical resources. This decision prioritizes both authentic appearance and multi-decade resilience.

Matching Stone Shape and Color to Your Design

Choosing the right stone veneer for an outdoor kitchen is a critical design decision. The stone’s shape and color should be a natural extension of the property’s architecture, whether the goal is a sleek, modern grilling station or a rustic, fieldstone hearth.

Our thin stone veneer is crafted from 100% real New England stone and is available in five distinct shapes and five regional color palettes. Each piece is precisely sawn to approximately one inch thick, providing the genuine look and feel of full-depth masonry without the associated weight and structural requirements. Matching corners are available for all shapes and colors.

Pairing Stone Shapes with Architectural Styles

The profile of the stone—its shape and how it is laid—has a significant impact on the final appearance. Clean, linear shapes lean contemporary, while irregular or rounded stones provide a more traditional, organic feel.

- Ledgestone & Ashlar: For a modern look, these rectilinear shapes create tight, stacked horizontal lines. Ledgestone’s thin strips are ideal for adding refined texture to a grill island or backsplash. Ashlar offers taller courses for a larger-scale statement, suitable for commercial patio kitchens or extensive residential projects.

- Square & Rectangular: This is a timeless, classic choice that delivers a formal, organized appearance. It pairs well with Colonial-style homes or any project requiring a clean, structured layout.

- Mosaic: For an authentic, hand-laid New England fieldstone look, Mosaic is the solution. Its irregular, angular pieces are suited for rustic outdoor fireplaces, chimneys, or retaining walls that integrate with the landscape.

- Round: Sourced from glacial deposits, Round stone has a weathered, cobblestone feel common in historic New England. It is an ideal choice for outdoor kitchens at farmhouses, lake homes, or heritage properties.

Our detailed stone veneer shapes comparison provides side-by-side visuals to illustrate how each profile functions in an application.

The table below outlines how each stone shape aligns with common outdoor kitchen designs, helping to select the appropriate match for a project’s aesthetic.

| Matching Stoneyard Stone Shapes to Outdoor Kitchen Styles |

| :— | :— | :— |

| Stone Shape | Visual Style | Common Outdoor Kitchen Use Cases |

| Ledgestone | Modern, sleek, linear, textured | Grill islands, backsplashes, contemporary water features |

| Ashlar | Bold, structured, contemporary | Large-scale kitchens, commercial patios, feature walls |

| Square & Rectangular | Traditional, formal, classic | Colonial-style homes, integrated fireplaces, formal seating walls |

| Mosaic | Rustic, organic, natural | Outdoor fireplaces, retaining walls, pizza ovens, country-style kitchens |

| Round | Historic, charming, weathered | Farmhouse kitchens, lakeside patios, heritage properties |

The right shape frames the entire mood of an outdoor space, turning a functional kitchen into a true architectural feature.

Selecting a New England Color Collection

The color blend is the final, critical touch that ties the outdoor kitchen to the home, patio, and surrounding landscape. The color of Stoneyard’s collections is integral to the stone, not a surface application. This is a key differentiator from the surface-level pigments found on manufactured products from brands like Eldorado Stone or Cultured Stone.

Unlike cement-based veneers that can fade or discolor under UV exposure, real New England stone possesses color and texture throughout its entire body. This ensures a natural patina develops over decades, rather than a degradation of artificial coatings.

Here are Stoneyard’s five signature color blends, each reflecting New England geology:

- Boston Blend®: Our most versatile collection, a mix of gray, tan, and brown tones that complements nearly any architectural style. Boston Blend Mosaic is a frequent choice for achieving a classic, multi-hued fieldstone look.

- Colonial Tan: Dominated by warm golds and earthy browns, this blend is well-suited for traditional or coastal designs.

- Greenwich Gray: A sophisticated, neutral gray palette ideal for modern and commercial projects. For a clean, high-end finish on a contemporary outdoor kitchen, Greenwich Gray Ashlar is an excellent choice.

- Newport Mist: Soft grays and whites in this collection are ideal for contemporary or coastal-inspired projects requiring a brighter appearance.

- Vineyard Granite: A rugged blend of gray and pink granite with natural mica flecks that reflect sunlight. It’s a perfect match for coastal homes or rustic designs where texture and character are desired.

Real Stone vs. Manufactured Veneer: What’s the Real Difference?

For a high-exposure area like an outdoor kitchen, material selection is critical for long-term performance. While real stone and manufactured veneer can appear similar initially, their composition dictates how they will perform over years of exposure to the elements.

This section compares the core properties of Stoneyard’s real New England stone versus the cement-based products from brands like Eldorado Stone, Coronado Stone, and Cultured Stone.

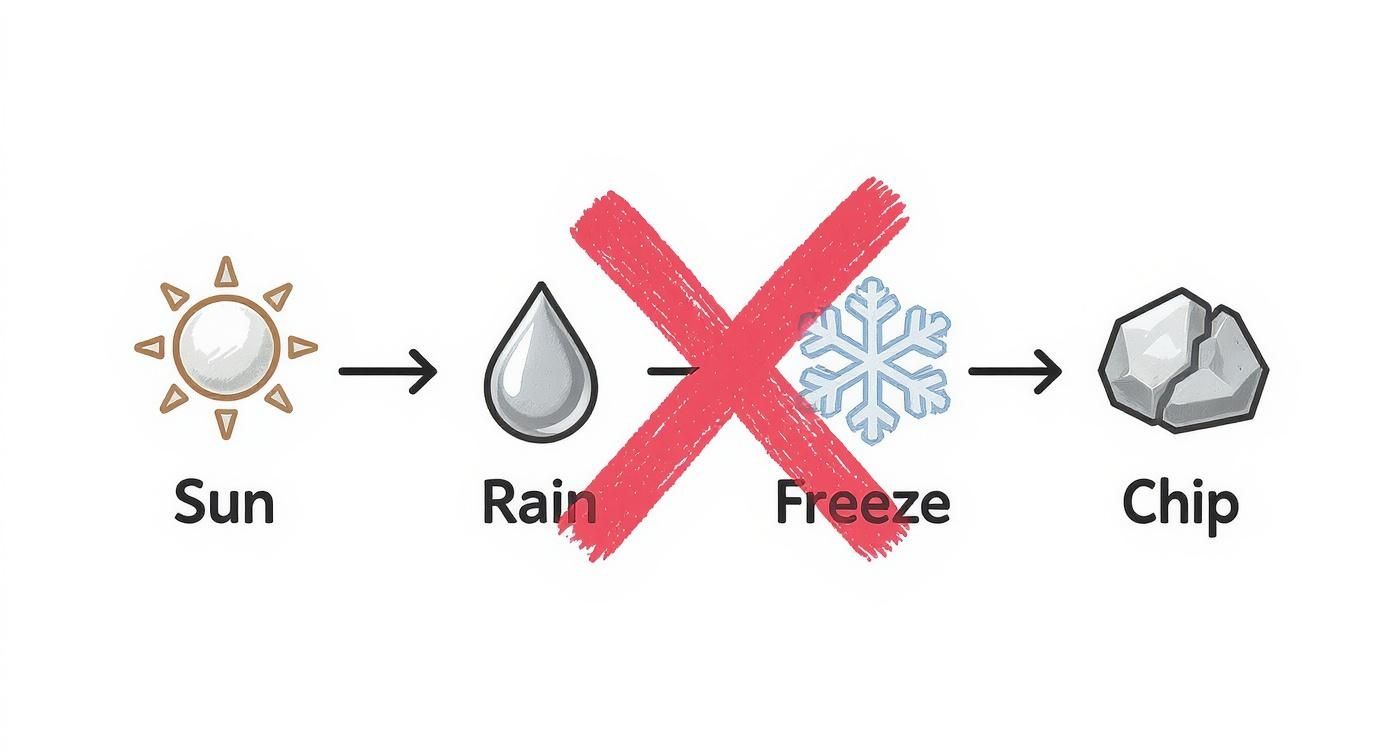

Manufactured veneers are concrete cast in molds and painted with pigments to mimic real stone. This process, while creating uniformity, is their primary weakness in exterior applications. Concrete is more porous than dense, geological stone, meaning it absorbs more water.

This is a significant problem in any climate with a freeze-thaw cycle. Moisture penetrates the veneer, freezes, expands, and creates micro-fractures. This process leads to chipping, cracking, and delamination of the pigmented surface layer.

Durability in Real-World Conditions

An outdoor kitchen must withstand more than just weather. Grease from a grill, spilled liquids, and cleaning chemicals can degrade the thin pigment layer on manufactured stone.

Once that color is compromised, the damage is permanent, leaving patches of plain gray concrete exposed.

Stoneyard’s 100% natural thin stone veneer is a fundamentally different material.

- Permanent Color: The color in our stone is the stone itself. The warm hues in Colonial Tan or the mica flecks in Vineyard Granite run through the entire body. It cannot fade, chip, or be discolored by UV exposure.

- Weather Resistance: Stone quarried from New England is naturally dense with very low porosity. All our products are Harsh Climate Approved (HCA)—they have superior resistance to the freeze-thaw cycles that degrade manufactured products.

- Chemical Resistance: Real stone is resistant to common cleaning products, allowing for effective maintenance without damaging the material.

This fundamental difference is why natural stone develops an authentic patina over time, while manufactured products simply degrade.

Long-Term Value and ROI

While the initial labor cost to install real and manufactured veneer can be similar, the long-term value is not comparable. A manufactured stone veneer will likely require repairs or replacement, particularly in harsh climates.

The real story is the total lifecycle cost. Natural New England stone veneer is a multi-decade investment that requires minimal maintenance and will not fade. This permanence translates directly into a higher return on investment and increases a property’s resale value.

The demand for durable outdoor living spaces is growing. The global stone veneer market is projected to reach $1.01 billion by 2035, with high-performance applications like outdoor kitchens driving much of that growth. You can review these market trends in this report from Vantage Market Research.

Choosing Stoneyard’s real stone veneer is a performance decision that ensures an outdoor kitchen maintains its appearance and structural integrity for the life of the home.

Prepping the Structure for a Lasting Installation

The performance of any stone veneer for an outdoor kitchen depends on the substrate. The authentic New England stone we provide from our Littleton, MA facility is designed for longevity, but it is only as durable as the surface it is attached to. A solid, stable, and waterproof foundation is non-negotiable for any outdoor build.

The stone veneer market reached $880.8 million recently and is projected to grow by 6.7% annually from 2025 to 2033. High-end residential projects like outdoor kitchens make up over 54% of this demand, making proper installation more critical than ever.

Preparing Framed Walls for Stone

For outdoor kitchens built with wood or metal framing, stone cannot be applied directly. A multi-layered, waterproof system is required to protect the structure from the elements.

The standard, code-compliant assembly is as follows:

- Two Layers of Weather-Resistant Barrier (WRB): This is the primary defense against water intrusion into the wall cavity, protecting the sheathing and framing.

- Metal Lath: A galvanized, self-furring metal lath is fastened over the WRB. This metal grid provides a mechanical key for the mortar to adhere to.

- Cementitious Scratch Coat: A ½-inch layer of mortar is troweled over the lath. While wet, it is “scratched” with a notched trowel to create horizontal grooves. Once cured, this rough surface provides an ideal bonding substrate for the thin stone veneer.

Working with Concrete and Masonry Walls

For kitchens built from concrete blocks (CMU) or poured concrete, surface preparation is more direct.

The objective is a clean, raw surface for mortar adhesion. This means removing any paint, sealers, or contaminants that could inhibit a strong bond. Typically, pressure washing is sufficient to prepare the surface for a direct application of polymer-modified mortar and stone veneer.

This infographic illustrates why proper substrate preparation is crucial. Natural stone is resilient, but it requires a base that matches its longevity.

Our Stoneyard Harsh Climate Approved stone is built to withstand severe weather. A great complementary project, like building a DIY outdoor pizza prep table, can add function and be finished with the same durable stone veneer.

A final critical detail: we provide matching 90-degree corner pieces for every stone style and color. These are essential for wrapping islands, columns, and edges to create a seamless, solid-stone appearance.

Getting Your Materials and Job Site Ready

A successful stone veneer project for an outdoor kitchen begins before the first batch of mortar is mixed. Accurate material calculation and proper job site preparation are key to avoiding delays and unexpected costs.

Calculating Your Stone Requirements

Estimating the required amount of real stone veneer is straightforward. It involves measuring the total area for flat pieces and the total length for outside corners.

- Calculate Flats: Measure the total square footage of all surfaces to be covered. Multiply the height and width of each section to get the area, then sum all sections for a grand total.

- Account for Openings: Subtract the square footage of any openings, such as grill cutouts, refrigerator doors, and access panels.

- Measure Corners: Measure the total linear feet of all outside 90-degree corners on islands, columns, and backsplashes.

Once you have the total square footage for flats and total linear feet for corners, you are ready to order.

A 5–10% overage on the flat stone calculation is recommended. This buffer accounts for cuts, fitting, and potential breakage during installation, ensuring sufficient material to complete the job.

Our online Stoneyard Thin Veneer Material Calculator simplifies this process. For more details, see our guide on how to calculate the amount of material needed for thin stone installations.

Job Site Logistics and Material Handling

Once your material is ordered, plan for its arrival. All of our Stoneyard natural thin stone veneer is crafted at our facility in Littleton, Massachusetts, USA, and shipped directly to your site.

Place pallets on level, solid ground as close to the work area as possible to minimize handling. Keep the stone covered with a tarp to protect it from dirt, mud, and rain. A clean surface on the back of each stone is vital for optimal mortar adhesion.

Common Questions About Outdoor Kitchen Stone Veneer

Here are factual answers to the most common questions we receive from builders and masons about using our New England thin stone veneer, direct from our team at the Littleton, MA facility.

Can Stoneyard Thin Veneer Be Installed Directly Over Wood Framing?

No. Natural thin stone veneer cannot be directly adhered to a wood-framed structure. A proper installation requires a multi-layer system.

This includes a weather-resistant barrier, metal lath, and a solid cementitious scratch coat. Once the scratch coat cures, the stone can be adhered using a high-quality, polymer-modified mortar. This method ensures a waterproof assembly, protects the underlying structure, and creates a permanent bond. Our official installation guide details the entire process.

How Does Real Stone Hold Up to Heat From a Built-in Grill?

This is a key performance advantage of real stone. Our 100% natural stone veneer is non-combustible and handles the high heat from a grill without issue. This contrasts with manufactured products like Eldorado Stone or Cultured Stone, which use pigments that can discolor when exposed to high temperatures. Real stone’s color and integrity are unaffected.

However, you must follow the grill manufacturer’s clearance requirements for combustible materials. The stone is non-combustible, but the wood framing behind it is not. Protect the underlying structure with non-combustible materials like cement board to meet all safety codes.

While the stone itself is fireproof, the entire wall assembly must be constructed to handle heat transfer safely. Stoneyard’s dense, authentic stone provides the fire-resistant finish, but the underlying structure must also comply with all fire codes.

What Is the Best Way to Clean and Maintain the Stone Veneer?

Our natural stone veneer is extremely low-maintenance due to its density. For routine cleaning, a pH-neutral stone cleaner and a soft-bristle brush are typically all that is needed. Avoid acidic or abrasive cleaners, which can damage the stone or mortar.

For grease splatters, a specialized stone poultice can be used to draw oil stains out of the stone without causing damage. Because our dense New England stone resists weathering far better than porous concrete veneers, your kitchen will maintain its appearance for decades with minimal care.

Are Corner Pieces Necessary for an Outdoor Kitchen Island?

Yes, they are 100% necessary for a professional result. To achieve the appearance of a solid stone structure, you must use matching 90-degree corner pieces.

These pieces wrap around edges and columns, providing an authentic, full-depth stone appearance while concealing the substrate and veneer edges. Without them, the thin profile of the stone is exposed at every corner, undermining the intended aesthetic. Corners are a critical component for achieving true craftsmanship.

Explore the full Stoneyard Thin Stone Veneer Collection — real New England stone, made in the USA.

Order free samples at https://stoneyard.com/stone-samples/ or schedule a virtual showroom visit at https://stoneyard.com/contact/.