A Builder’s Guide to Interior Columns Wraps

When structural columns disrupt a room’s design, wrapping them in real stone veneer is a professional-grade solution. This process uses 100% natural, sawn-thin stone to fully encase a column, transforming a standard support into a durable architectural feature. The result is the authentic appearance of solid masonry without the weight or need for a dedicated structural footing.

This permanent, high-performance solution is suitable for residential great rooms and commercial lobbies alike.

Turning a Problem into a Centerpiece with Authentic Stone

Structural columns in basements, open-concept living areas, and commercial spaces can be a design challenge. They are essential for support but can interrupt the flow of a room. Wrapping them in real New England stone veneer is a practical and visually effective solution that turns a functional element into a focal point.

This is where the distinction between real stone and synthetic options is most apparent. Unlike PVC or vinyl wraps, natural thin stone veneer from Stoneyard, Inc. offers authentic texture, color variation, and permanence. Each piece is genuine fieldstone or quarried stone, crafted at our facility at 2 Spectacle Pond Rd, Littleton, Massachusetts. This ensures no two columns are identical, adding unique character and long-term value that manufactured products cannot replicate.

Performance and Durability in Interior Applications

Applying real thin stone veneer is a builder-focused method for achieving a classic masonry appearance with modern construction techniques.

Key benefits include:

- The Look of Full-Depth Stone: Using matching corner pieces, the finished column is visually indistinguishable from one built with heavy, full-bed stone, creating a seamless, authentic look.

- A Lighter Structural Load: Stoneyard thin veneer weighs approximately 13-15 lbs per square foot. This allows for direct application to standard framed columns without requiring new concrete footings.

- A Truly Permanent Finish: For interior use, real stone is a zero-maintenance material. Its color is integral to the stone itself and will not fade, chip, or peel like pigmented concrete products from competitors such as Eldorado Stone or Cultured Stone.

- Design Flexibility: With five distinct stone shapes and five New England color collections, the material can match any architectural style. Options range from the clean, contemporary lines of Boston Blend® Ledgestone to the rustic charm of Colonial Tan Round.

The demand for solutions that are both protective and decorative is increasing. The market for column protectors and wraps is projected to grow significantly, highlighting the value builders and designers place on enhancing necessary structural elements.

While other materials exist, such as those detailed in this guide to custom vinyl wall stickers and furniture wraps, real stone provides unmatched durability and authenticity for permanent installations.

Why Real New England Stone Outperforms Manufactured Alternatives

The choice between real, authentic stone and manufactured alternatives for an interior column wrap directly impacts the project’s appearance, durability, and long-term value. Products from brands like Eldorado Stone, Coronado Stone, and Cultured Stone are fundamentally different from the natural stone processed at Stoneyard.

These competing products are cement-based veneers, cast in molds and tinted with pigments to imitate the look of natural stone. The color and texture exist only on the surface.

Stoneyard thin stone veneer is 100% real New England stone, quarried or sourced from fields and sawn to approximately one inch thick. The color, texture, and character are consistent throughout the entire body of the stone, a result of its natural geological formation. This difference is critical for performance in high-traffic interior spaces.

Material Integrity and Durability

The primary weakness of manufactured stone is its pigmented surface. A scratch or chip from furniture or equipment can expose the gray concrete beneath the thin colored layer, creating a blemish that is difficult to repair. Over time, UV exposure from windows can cause these pigments to fade.

Real stone does not have this vulnerability. If a piece of Stoneyard veneer chips—a rare event due to the stone’s density—it simply reveals more of the same natural stone underneath. Its color is geological and permanent.

Natural New England stone veneer delivers multi-decade performance with minimal maintenance and no color fading.

Performance Under Real-World Conditions

Interior columns are subject to daily wear and tear from bumps and scrapes. These impacts can easily damage manufactured products, leading to visible degradation.

Stoneyard’s genuine New England stone is Harsh Climate Approved (HCA), meaning it is naturally dense and durable enough for the most severe outdoor freeze–thaw cycles. This inherent strength translates directly to indoor use, ensuring the column wrap remains pristine for the life of the building.

Natural Stone vs. Manufactured Stone for Column Wraps

A side-by-side comparison clarifies the long-term performance differences between these materials.

| Attribute | Stoneyard Natural Thin Stone Veneer | Manufactured Stone (Eldorado, Cultured Stone) |

|---|---|---|

| Material Composition | 100% real New England quarried or fieldstone | Pigmented concrete cast in molds |

| Color Source | Natural, through-body geological color | Surface-applied pigments |

| Durability | High-density, chip and scratch-resistant | Prone to chipping, scratching, and surface wear |

| Long-Term Appearance | Develops a natural patina; color is permanent | Can fade from UV exposure; damage reveals aggregate |

| Maintenance | Virtually zero; clean with water if needed | Requires careful cleaning to avoid damaging surface color |

| Resale Value | Adds significant, lasting value to the property | Offers minimal long-term investment return |

While installation labor costs are similar, the long-term performance and value differ significantly. Choosing authentic New England thin stone veneer is an investment in permanence and genuine craftsmanship that manufactured alternatives cannot match.

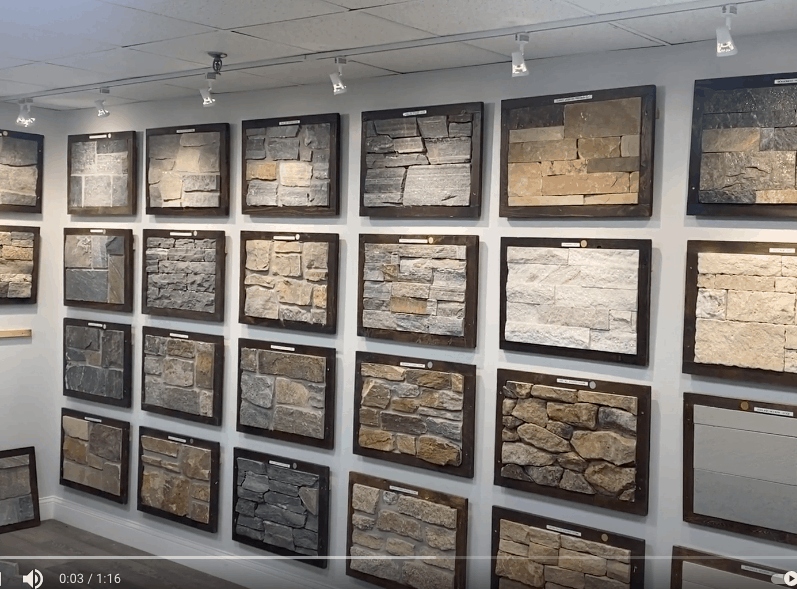

Choosing the Right Stone Shape and Color Profile

Selecting the correct stone profile is what transforms a simple interior column into a significant architectural feature. The chosen shape and color combination will define the aesthetic of the space, whether it is a commercial lobby or a residential great room.

Stoneyard offers five distinct stone shapes, each providing a different look and feel for a column wrap.

The material, sourced and crafted at our Littleton, MA facility, connects directly with the project’s design vision. The choice is about selecting a profile that aligns with the building’s architectural language.

Aligning Stone Shape with Architectural Style

The geometry of the stone dictates the column’s overall pattern and texture. Linear shapes create a clean, contemporary appearance, while irregular shapes provide a more rustic feel.

Our five shapes cover the full design spectrum:

- Ledgestone & Ashlar: Both are rectilinear shapes suited for modern and transitional designs. Ledgestone consists of thin, stacked strips that create texture and strong horizontal lines. Ashlar features taller courses for a larger, more formal scale appropriate for grand entryways or corporate spaces.

- Square & Rectangular: This profile offers a classic, orderly look often seen on colonial-style homes and traditional buildings, providing a timeless, structured appearance.

- Mosaic: With its irregular, angular pieces, Mosaic replicates the look of a traditional, hand-laid New England fieldstone wall. It is ideal for creating a rustic focal point in a mountain lodge or country club.

- Round: This profile uses weathered, cobblestone-style fieldstones, perfect for achieving a historic, farmhouse, or coastal cottage aesthetic.

For more detailed comparisons, our guide on the different shapes of natural thin stone veneer includes project photos and applications.

Pairing Shapes with New England Colors

Pairing a shape with the right color blend completes the design. Stoneyard’s five New England color collections are sourced from regional geology, providing authentic tones that pigmented concrete cannot replicate.

The combination of a specific shape and a natural color blend brings an interior column wrap to life. A Boston Blend® Ledgestone column has a completely different feel from a Colonial Tan Round one, though both are crafted from the same high-quality New England stone.

Practical pairings include:

- Boston Blend® Ledgestone: The mix of gray, tan, and brown in a clean, linear format is highly adaptable for modern commercial lobbies and contemporary homes.

- Greenwich Gray Ashlar: Neutral gray tones and larger blocks create a sophisticated look suitable for university buildings, corporate interiors, and minimalist residential designs.

- Colonial Tan Round: Warm gold and brown cobblestones are an excellent choice for wrapping columns in finished basements, particularly in farmhouse-style designs.

- Vineyard Granite Mosaic: This gray-pink granite with mica sparkle, set in an irregular pattern, delivers a rugged, refined look ideal for coastal homes or boutique hotels.

Stone columns are a key element in many design trends, including modern farmhouse design ideas. A thoughtful combination of shape and color ensures the interior column wrap is a powerful and authentic architectural statement.

Getting Technical: Planning Your Stone Veneer Column Wrap

A professional-grade stone column wrap requires careful technical planning before installation begins. Proper preparation is the foundation of a permanent, high-quality result.

Each column substrate—whether wood-framed, a steel I-beam, or a concrete lally column—requires specific preparation before mortar and stone can be applied.

Prepping the Column Substrate

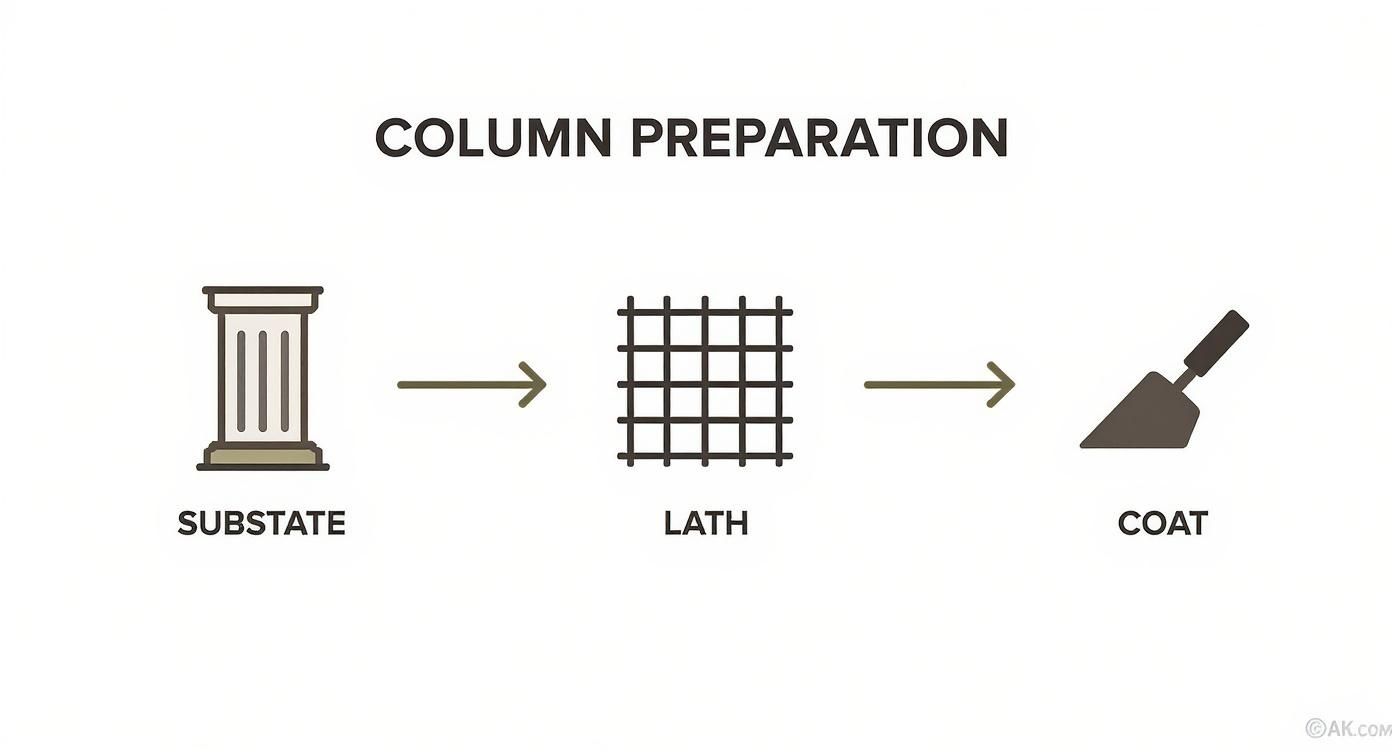

For non-masonry surfaces, a suitable substrate must be created. The standard method involves wrapping the column with a weather-resistant barrier, securing metal lath, and applying a ½-inch thick scratch coat of mortar. This provides a solid, textured surface for maximum adhesion and durability.

This preparation aligns with modern building science principles focused on moisture control. The broader U.S. house wraps market, as detailed by Arizton Advisory & Intelligence, reflects the industry’s focus on proper building envelopes. These same principles ensure an interior column is ready for a flawless stone finish.

The Secret to an Authentic Look: Matching Corner Pieces

To achieve the appearance of a solid stone column, using matching 90-degree corner pieces is essential. These are not two flat pieces joined together; they are L-shaped units sawn from a single block of real New England stone.

Installed at the corners, these pieces create a seamless, authentic look from every angle, eliminating the need to miter flat stones—a shortcut that can expose cut edges and compromise the illusion of solid masonry. Stoneyard crafts corners for every stone shape and color blend to ensure a perfect match.

Using matching corners is the only way to make a thin veneer column wrap look indistinguishable from a traditional, full-bed stone structure. It’s the key to achieving true architectural authenticity.

Nailing the Material Estimate

Accurate material calculation prevents project delays and waste. Two separate measurements are needed for a column wrap:

- Flats (Square Footage): Calculate the total surface area of the column’s four sides to determine the amount of flat stone veneer required.

- Corners (Linear Footage): Measure the total height of all four corners to determine the linear feet of corner pieces needed.

The Stoneyard Thin Veneer Material Calculator simplifies this process. Input the column’s dimensions, and the tool calculates the exact amount of flats and corners required.

For a complete overview of the installation process, refer to our detailed guide on how to install thin stone veneer columns.

Installation and Finishing Best practices

A successful column wrap depends on precise installation techniques. The process begins with proper surface preparation and requires careful execution at each step to ensure a durable and visually appealing result.

This workflow of substrate, lath, and scratch coat provides the ideal surface for mortar adhesion, guaranteeing a permanent, professional-grade bond.

Setting the Stone with Precision

Always begin setting stone at the base of the column and work upward. This technique uses gravity to support each course as the mortar cures.

Apply a consistent ½-inch layer of mortar to the back of each stone (“back-buttering”). Press each piece firmly into the scratch coat with a slight wiggling motion to remove air pockets and ensure a strong bond.

A critical step is interlocking the corner pieces as you build. By alternating the long and short legs of the 90-degree corners with each course, you create that authentic, staggered look you see in traditional masonry. This doesn’t just look better; it adds significant structural integrity to the entire wrap.

Choosing Your Jointing Style

The joint style plays a significant role in the column’s final appearance and should complement the space’s architecture.

The two primary options are:

- Dry-Stacked Joint: For a clean, modern aesthetic, stones are fitted tightly together with no visible mortar. This method requires precise cutting and is well-suited for linear shapes like Ledgestone or Ashlar.

- Traditional Grouted Joint: This classic approach leaves a consistent gap (typically ⅜ to ½ inch) between stones, which is later filled with grout. It highlights the unique shape of each stone and is ideal for rustic profiles like Mosaic or Round.

The Final Steps to Completion

After the stone is set and the mortar has cured, finishing details complete the project. For a grouted joint, apply grout carefully, filling all voids. Use a pointing tool to shape the joints for a clean, professional finish.

A column is not complete without a cap. For information on finishing the top surface, see our guide on how to cap stone veneer columns.

A final cleaning with a stiff brush and water will remove any mortar dust, revealing the true color and texture of the natural New England stone.

Your Top Questions About Stone Column Wraps

Here are straightforward answers to common questions about using natural stone for interior columns, based on decades of experience with Stoneyard’s New England thin stone veneer.

Can Thin Veneer Be Applied Over a Round Column?

Yes, but the stone cannot be applied directly to a curved surface. Real natural thin stone veneer requires a flat substrate for a proper mortar bond.

The standard professional practice is to “box in” a round lally column by building a square or rectangular frame around it with wood studs and cement board. This provides the necessary flat surfaces for the stone and allows for the use of matching 90-degree corner pieces, resulting in a seamless appearance that looks like solid stone.

How Much Weight Does a Stone Column Wrap Add?

Stoneyard’s natural thin stone veneer weighs only 13–15 pounds per square foot, approximately one-third the weight of full-bed stone.

This low weight allows for installation on interior columns without requiring new structural footings or specialized supports, making it suitable for both new construction and renovations.

What Is the Maintenance Difference Between Real and Faux Stone?

The key difference is permanence.

Real New England stone from Stoneyard is virtually maintenance-free for interior applications. Its color is an integral part of the stone and will never fade, peel, or flake off.

Manufactured faux stone from competitors like Eldorado Stone or Cultured Stone is pigmented concrete with surface-level color. A chip or scratch can expose the gray aggregate underneath. The pigments can also fade over time from indirect sunlight. With real stone, the color is the stone, ensuring it lasts for generations.

Are Special Tools Required for a Column Installation?

No special tools are required. A mason experienced with high-quality tile or traditional stone will be familiar with the process. Interior columns wraps are installed using standard masonry tools: a trowel, level, hammer, and a masonry saw with a diamond blade for custom cuts.

For detailed technical specifications and best practices, professionals can find a complete installation guide and other resources on the Stoneyard Contractor Resources page.

Explore the full Stoneyard Thin Stone Veneer Collection — real New England stone, made in the USA.

Order free samples at https://stoneyard.com/stone-samples/ or schedule a virtual showroom visit at https://stoneyard.com/contact/.