A Builder’s Guide to Real Natural Ledgestone Veneer

When builders and architects specify “ledger stone panels,” the term often refers to pre-assembled sheets of stone designed for quick installation. However, for projects demanding authentic craftsmanship and long-term performance, it’s critical to distinguish between manufactured products and Stoneyard’s Ledgestone, which consists of individual pieces of real New England stone. This piece-by-piece method allows a skilled mason to achieve a genuine, hand-laid stacked stone wall that manufactured panels cannot replicate.

What is Natural Ledgestone Veneer?

Unlike cement-based products cast in molds, Stoneyard’s Ledgestone is not a uniform, pre-made panel. Each piece is 100% natural fieldstone or quarried stone, sourced from New England and crafted at our Littleton, Massachusetts facility.

These long, linear strips of real stone are sawn to an approximate thickness of one inch (ranging from ¾ to 1¼ inches). This creates a lightweight, versatile thin stone veneer that delivers the appearance of full-bed stone without the structural requirements. For builders who prioritize authenticity and durability over the repetitive patterns of faux stone, this distinction is fundamental.

Individual Pieces vs. Faux Panels: The Stoneyard Difference

Working with individual stones provides the flexibility to create a completely custom, high-end installation. A mason can hand-select and set each piece, controlling joint tightness and overall pattern for a result impossible to achieve with manufactured panels from brands like Eldorado Stone or Cultured Stone, which are often prone to unnatural seams and repetitive textures.

Key advantages of Stoneyard’s natural Ledgestone:

- Authentic Appearance: Every installation is unique, featuring a non-repeating pattern that reflects real New England geology.

- Full-Depth Stone Appearance: We offer matching corners for every color blend, which wrap around edges to create the convincing look of a solid, structural stone wall.

- Design Flexibility: The thin, straight-edged shape allows for tight horizontal joints, delivering the clean, stacked lines ideal for projects ranging from residential fireplaces to commercial façades.

While the end-use is similar, natural stone and manufactured panels differ fundamentally in material composition, performance, and longevity.

Natural Ledgestone vs Faux Ledger Panels

| Feature | Stoneyard Natural Ledgestone | Manufactured Stone Panels |

|---|---|---|

| Material | 100% real quarried or fieldstone sourced and made in New England, USA. | Cement, aggregates, and artificial pigments cast in molds. |

| Appearance | Unique, one-of-a-kind pieces with color and texture throughout the stone. | Repetitive patterns; color is a surface-deep coating. |

| Durability | Lasts for decades; color will not fade, chip, or flake. | Prone to fading, chipping, and delamination, revealing the gray cement base. |

| Installation | Individual pieces are hand-laid by a mason for a custom, seamless look. | Panels are installed in sheets, often resulting in visible seams. |

| Weight | Lightweight thin veneer (approx. 13 lbs/sq ft). | Generally lighter, but less dense and durable. |

| Climate Resistance | Harsh Climate Approved (HCA); naturally withstands freeze-thaw cycles. | Can absorb water, leading to cracking or deterioration in freezing climates. |

Manufactured panels may offer installation speed, but they cannot match the enduring performance and authentic character of real natural stone.

By using individual pieces of sawn stone, you achieve a level of craftsmanship and permanence that manufactured panels simply cannot replicate. The final result is a true masonry finish, not a surface covering.

While some builders may opt for pre-assembled panels for speed, you can explore Stoneyard’s natural stone panels that are crafted for a genuine look. The inherent strength and freeze-thaw durability of real New England stone ensure your project will maintain its color and structural integrity for decades, even in the harshest climates.

The Unmatched Durability of New England Stone

For exterior siding, outdoor kitchens, or any application exposed to the elements, material durability is non-negotiable. Real New England thin stone veneer from Stoneyard is an investment in performance, engineered by nature over millennia. This geological resilience is why every product we offer is Harsh Climate Approved (HCA).

This designation confirms our stone is tested and proven to withstand punishing freeze-thaw cycles common in New England. As temperatures drop, moisture absorbed by porous materials expands, creating immense internal pressure that can cause cracking, spalling, or delamination.

Because our real natural stone is exceptionally dense with low water absorption, it resists this destructive cycle, ensuring it maintains its structural integrity and appearance for decades.

Real Stone vs. Manufactured Alternatives

This natural durability stands in stark contrast to manufactured stone. Competing products from Eldorado Stone (https://eldoradostone.com), Coronado Stone (https://coronado.com), and Cultured Stone (https://www.culturedstone.com) are cement-based veneers.

These porous concrete products can absorb significant amounts of water. When that moisture freezes, common failures include:

- Delamination: The colored surface flakes or peels away from the concrete base.

- Cracking: The material develops fractures, compromising its appearance and weather resistance.

- Color Fading: Artificial pigments, often just a surface coating, fade under UV exposure and harsh weather.

With the U.S. stone veneer market expected to grow, as noted in reports on growth trends in the stone veneer market, builders and property owners are increasingly seeking durable, authentic materials that provide long-term value.

The Inherent Advantage of Natural Color

A critical differentiator is that the color and texture of Stoneyard’s natural stone run completely through each piece. The grays of our Boston Blend® or the warm tones of Colonial Tan are not stains; they are the result of geological formation. This means the color will never flake off, peel away, or fade.

Natural New England stone veneer delivers multi-decade performance with minimal maintenance and no color fading.

This durability ensures your project will not only look exceptional upon completion but will continue to perform and maintain its beauty for the life of the building. Over time, the real stone develops a natural patina that enhances its character without compromising its strength.

Where to Use Ledgestone and Ashlar

The clean, horizontal lines of Ledgestone and Ashlar shapes are highly versatile, specified for sleek modern residences and traditional commercial buildings alike. These straight-edged strips of real New England stone deliver a structured, sophisticated appearance.

While often used interchangeably, Ledgestone and Ashlar have distinct characteristics. Ledgestone consists of thin strips, creating a fine texture with tight, stacked joints. Ashlar utilizes taller courses, providing a larger scale suitable for expansive walls.

In Residential Design

Incorporating these stacked stone shapes adds authentic texture and regional character to home projects. Their linear format pairs well with other materials like wood siding or stucco, creating a high-end, custom aesthetic.

Common residential applications include:

- Exterior Siding: A façade of Boston Blend® Ledgestone on a modern farmhouse is a perfect example of timeless meets contemporary.

- Fireplaces: A floor-to-ceiling fireplace in Vineyard Granite Ashlar becomes a focal point, with gray-pink hues and mica flecks adding natural character.

- Outdoor Kitchens: The tight joints of Ledgestone are ideal for backsplashes and surrounds in outdoor living spaces, providing a clean, durable finish.

- Accent Walls: An interior feature wall is an effective way to introduce natural materials. For more on this, see our guide on choosing the perfect stone accent wall.

The key to effective design is matching the stone’s scale to the project’s size. Ledgestone is ideal for detailed work like fireplaces, while Ashlar provides the visual weight needed for large exterior siding applications.

In Commercial and Public Spaces

For commercial projects, Ledgestone and Ashlar convey permanence and quality. Architects specify them for projects that require a sense of stability and craftsmanship.

Common commercial applications include:

- Building Facades: A retail storefront in Greenwich Gray Ashlar offers a neutral, modern look that elevates a brand’s presence.

- Hotel Lobbies: An accent wall behind a reception desk in Newport Mist Ledgestone creates a light, welcoming, and contemporary atmosphere.

- Restaurant Interiors: The warm gold and brown tones of Colonial Tan Ledgestone can define a dining space, adding texture that is both rustic and refined.

- University Buildings: The classic, orderly appearance of Ashlar is a natural fit for academic and civic buildings, blending tradition with modern construction.

Exploring the New England Stone Palette

The color in natural thin stone veneer is not a surface-level pigment; it is an authentic reflection of New England’s geology. Each piece of fieldstone or quarried stone carries the unique mineral signature of its origin.

This through-body coloration is a significant advantage. The stone’s color will never fade, flake, or peel—a performance guarantee that manufactured concrete alternatives cannot match.

At our facility in Littleton, Massachusetts, we hand-sort this authentic stone into five distinct color collections. These curated palettes make it easy for builders and designers to match any architectural style, from a rustic farmhouse to a sleek commercial building. The natural variation from piece to piece ensures an authentic look that concrete products from repeating molds cannot achieve.

Stoneyard’s Five New England Blends

Selecting the right color blend is crucial for achieving the desired project outcome. We offer a real stone solution for every aesthetic, from the warm tones of a coastal home to the cool neutrals of a modern office.

Boston Blend®: Our signature collection, Boston Blend®, is a balanced mix of gray, tan, and brown with occasional weathered faces. Its versatile palette makes it suitable for nearly any project, from residential siding to university buildings.

Colonial Tan: Featuring warm golds, rich browns, and soft tans, Colonial Tan is ideal for creating inviting spaces in classic colonial homes, rustic fireplaces, and coastal cottages.

Greenwich Gray: For a sophisticated look, Greenwich Gray offers a range of cool to warm grays. Its clean appearance is perfect for modern aesthetics in commercial facades and contemporary homes.

Newport Mist: To achieve a light and airy feel, Newport Mist provides soft grays and subtle white tones. It is a popular choice for modern coastal properties and bright interior accent walls.

Vineyard Granite: This is genuine New England granite, defined by distinctive gray and pink tones with a classic black and white mica sparkle. Its rugged texture makes it a powerful choice for foundations and chimneys.

No matter which collection you choose, you’re getting the same high-performance stone that’s Harsh Climate Approved (HCA) for freeze-thaw durability. The selection process isn’t about performance—it’s purely about finding the perfect aesthetic for your project.

By understanding these palettes, you are not just specifying a stone shape; you are choosing an authentic piece of New England’s landscape to bring a vision to life.

Installing Natural Thin Stone Veneer

Natural thin stone veneer installation is a straightforward process for qualified masons. Each piece of Stoneyard Ledgestone is set by hand over a properly prepared substrate, such as masonry, concrete, or framed walls with metal lath and a cement scratch coat. This method creates a permanent, monolithic bond suitable for any project.

A primary advantage for builders is the material’s reduced weight. Sawn to approximately one inch thick, it weighs about one-third as much as full-depth stone. This eliminates the need for a structural brick ledge or additional foundation support, simplifying construction and expanding design possibilities.

Choosing the right stone starts with the project’s aesthetic goals. This chart helps connect design style and desired mood with the appropriate New England stone blend.

As shown, the architectural style serves as a starting point, leading to a color palette that makes the final stone choice feel intentional and cohesive.

Achieving a Full-Depth Appearance

The key to making thin veneer indistinguishable from a solid stone wall is the use of corners. We fabricate matching corner pieces that are cut to wrap seamlessly around edges, columns, and window returns. This detail eliminates visible joints and creates the authentic look of traditional full-bed masonry.

The demand for stone veneer, including ledger styles, continues to grow. Trends noted in publications like this one about the natural stone cladding market trends at verifiedmarketreports.com show that architects and builders recognize the value of materials that combine performance with aesthetics.

Installation Labor and Long-Term Value

Installation labor for real thin stone veneer is comparable to that for manufactured alternatives from brands like Cultured Stone or Coronado Stone. However, the long-term value proposition is vastly different. Natural stone is a one-time investment. Our stone’s Harsh Climate Approved (HCA) rating signifies it is built to last, with no fading, cracking, or delamination during freeze-thaw cycles.

This durability saves property owners significant repair and replacement costs often associated with cement-based products. Understanding how different materials contribute to a project’s success is a core component of the building trades. To learn more, explore these resources on careers in construction.

For detailed technical specifications, professionals should always consult official documentation to ensure every installation meets best practices and is built to last.

For comprehensive information, review your guide to thin stone veneer installation, which covers everything from surface preparation to final finishing. Proper technique is essential for showcasing the timeless beauty of real New England stone.

Real Stone’s Edge Over Faux Panels

Material selection requires consideration of long-term performance and total cost of ownership. At first glance, manufactured panels from brands like Eldorado Stone (https://eldoradostone.com) and Cultured Stone (https://www.culturedstone.com) may seem convincing, but their composition reveals significant disadvantages compared to real New England stone.

These products are concrete veneers, cast in molds and painted with pigments to imitate natural stone. This process results in a porous material that absorbs moisture. In climates with freezing temperatures, this trapped water expands, leading to cracking, surface delamination, and eventual failure.

In contrast, Stoneyard’s natural stone veneer is incredibly dense and has very low water absorption. This inherent quality is why it is Harsh Climate Approved (HCA), engineered by nature to withstand harsh weather for decades without degradation.

True Character and Resale Value

The difference between real and manufactured stone becomes more apparent over time. The color on manufactured stone is a surface treatment that can fade with UV exposure or chip off, revealing the gray concrete base. With Stoneyard’s real stone, the color and texture are integral to each piece. It may develop a natural patina over time, but it will never fade or flake.

This durability translates to a better return on investment. The global market for natural stone cladding, including styles like ledgestone, has seen steady growth. As noted in reports on natural stone cladding market trends at verifiedmarketreports.com, this reflects a clear preference among architects and builders for materials that are both beautiful and built to last.

While initial installation costs may be similar, the long-term value is not comparable.

Natural New England stone veneer gives you performance that lasts for decades with hardly any maintenance and zero color fading. That adds real resale value you just don’t get with concrete-based lookalikes.

Choosing real stone is about more than appearance; it’s a commitment to performance, authenticity, and permanence. It ensures a project maintains its beauty and structural integrity for the life of the building. For professionals focused on true craftsmanship and lasting quality, real New England thin stone veneer is the clear choice.

Answering Your Top Questions

Here are answers to common questions about natural thin stone veneer.

Are These Actual Panels or Individual Stones?

Stoneyard’s Ledgestone is 100% real New England stone, supplied as individual pieces. We do not offer prefabricated panels made from cast concrete, like those from brands such as Eldorado Stone. A mason installs each stone one by one, which allows for a truly custom, traditional stacked stone wall with natural, non-repeating joints.

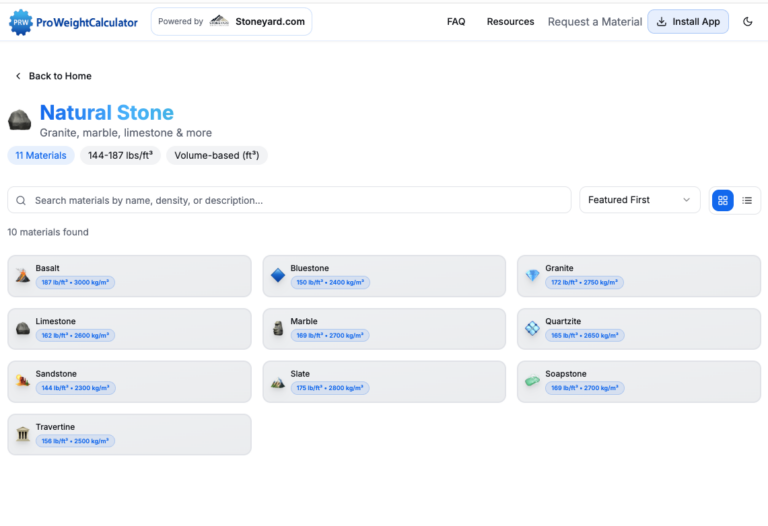

How Much Does Thin Stone Veneer Weigh?

One of the key advantages of our thin stone veneer is its weight. Because we saw the stone to approximately one inch thick, it typically weighs around 13 pounds per square foot. This is significantly less than traditional full-bed building stone. The reduced weight means you do not need a poured foundational brick ledge for support, expanding its application possibilities. You get the full-depth appearance, complete with matching corners, without the heavy structural load.

Can I Install Thin Stone Veneer Over Siding?

No, natural thin stone veneer cannot be installed directly over existing siding. For a permanent and weather-tight installation, the existing siding must be removed. On a framed wall, proper installation requires preparing the substrate with a weather-resistant barrier, attaching metal lath, and applying a cement scratch coat. The stone is then set in mortar onto this prepared surface.

For a deep dive into the proper techniques and best practices, always refer to the official Stoneyard Installation Guide.

Explore the full Stoneyard Thin Stone Veneer Collection — real New England stone, made in the USA.

Order free samples at https://stoneyard.com/stone-samples/ or schedule a virtual showroom visit at https://stoneyard.com/contact/.