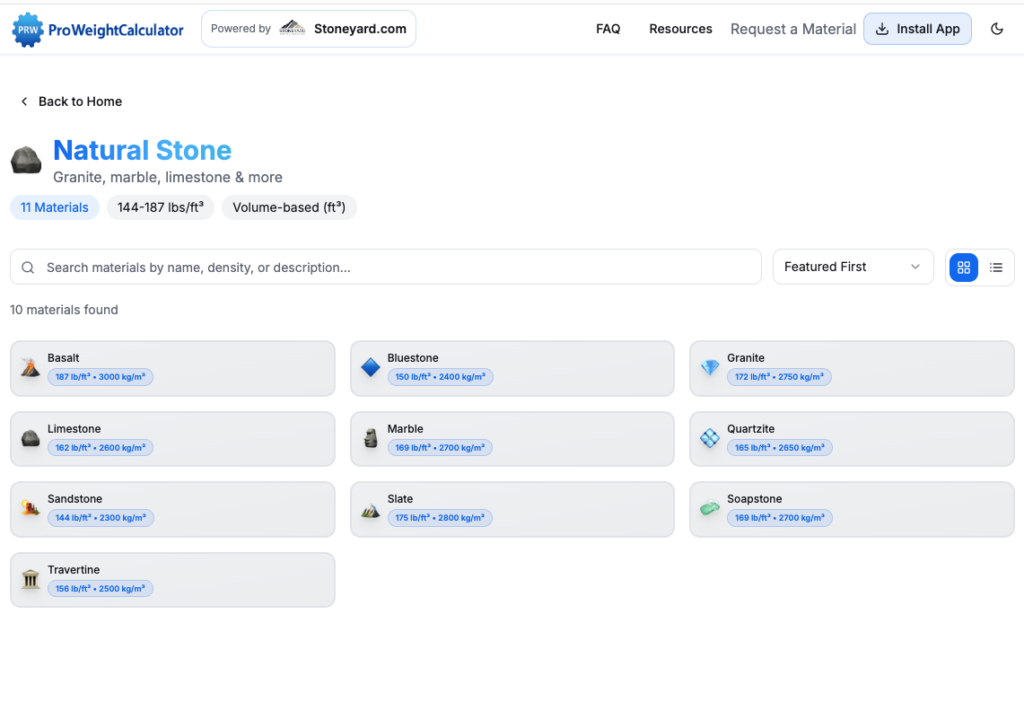

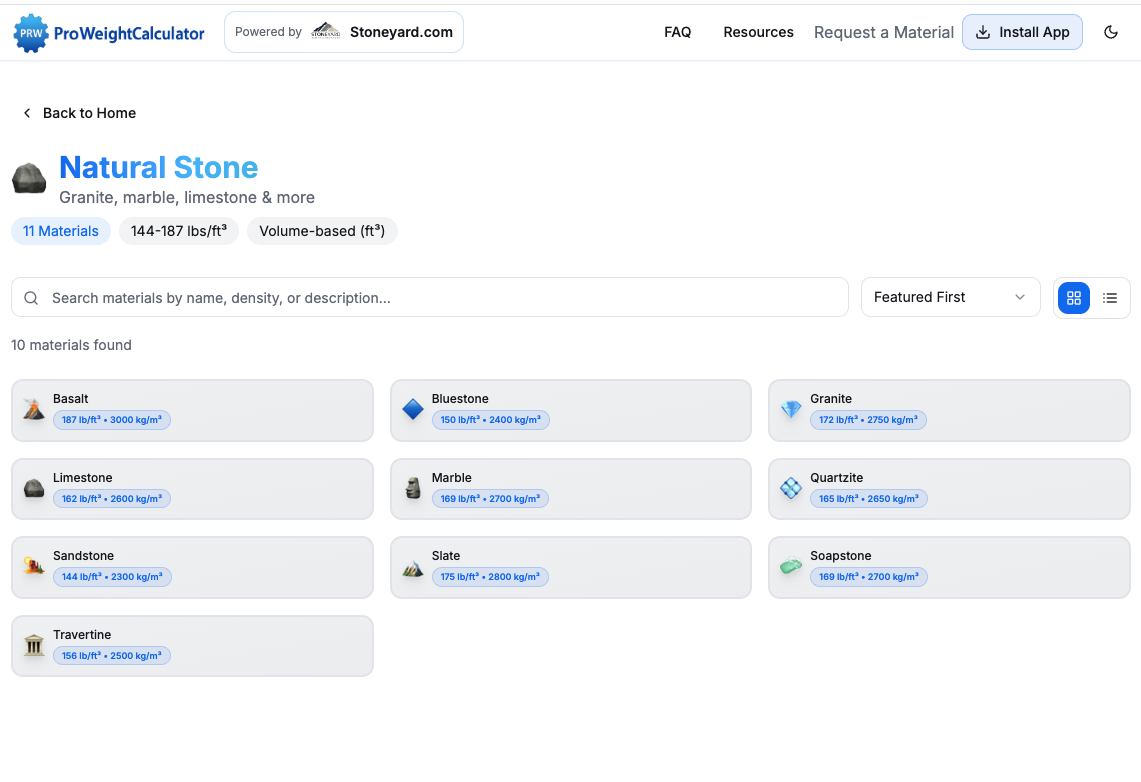

Stone Weight Calculator

Planning Tool

Stone Weight Calculator: Estimate Loads Before Delivery Day

Stone projects look simple on paper until delivery and handling get real. This calculator helps you estimate total weight fast, so you can plan the right truck, the right equipment, and the right staging before materials arrive.

TL;DR

- The project is medium to large.

- Access is tight, sloped, soft, or gated.

- You are scheduling a forklift, lull/telehandler, or crane.

- You are planning multiple drops or phased installs.

What it does

The Stone Weight Calculator gives a practical weight estimate for common stone applications.

That number becomes a planning tool you can use with your supplier, your delivery team, and your installer.

- Delivery planning and truck selection

- Equipment matching (capacity at working reach)

- Staging, sequencing, and jobsite efficiency

- Reducing surprises, delays, and extra charges

Why stone weight matters

Most problems happen when invisible details are not handled early. Weight is one of those details.

- Delivery planning: Weight impacts truck selection, lift-gate requirements, and access options.

- Jobsite access: Tight turns, soft ground, steep grades, and overhead clearance can limit delivery and staging.

- Handling equipment: Weight affects whether you need a pallet jack, forklift, lull/telehandler, or crane.

- Staging and sequencing: Better staging cuts labor and reduces the chance of moving heavy material twice.

- Reducing surprises: Fewer last-minute changes means fewer delays and fewer added charges.

How to use the calculator in a practical way

A weight estimate is most useful when it becomes a decision-making tool, not just a number.

- Estimate the weight using your best current measurements.

- Share the estimate with your supplier and confirm typical pallet or crate weights.

- Confirm delivery access (turning radius, driveway width, grade, ground conditions, overhead clearance).

- Match equipment to the plan and verify capacity at the working reach and height.

- Plan staging so material is placed once and handled as little as possible.

Common mistakes this helps prevent

- Assuming one pallet is always manageable

- Scheduling delivery without confirming access and turning radius

- Underestimating equipment needs (capacity and reach)

- Staging too far from the work area and adding labor time

- Not planning multiple drops for phased or large jobs

Pro Tip

Run the weight estimate before you lock delivery day. It is easier to adjust logistics early than to fix it when the truck arrives.

Note

Use estimates for planning, then confirm final weights. Final totals vary by stone type, thickness, moisture, packaging, and pallet configuration.

Warning

Do not exceed equipment capacity. Capacity drops with reach and height. Always verify working capacity, not the maximum rated number.

Use this alongside Stoneyard project calculators

Weight is one piece of planning. Coverage, quantities, and packaging matter too. Start with scope, then sanity-check logistics.

FAQs

Is a stone weight estimate accurate enough for delivery planning?

It is accurate enough for early planning and decision-making. Use it to set expectations, then confirm final packaging and handling requirements with your supplier and carrier.

What factors can change the final weight?

Stone density, thick