Best Mortar for New England Thin Stone Veneer Guide

Selecting The Best Mortar For Stone Veneer

Stoneyard’s real natural New England thin stone veneer, crafted at our Littleton, MA facility, sets the bar for authentic performance in Harsh Climate Approved (HCA) applications. Every piece is 100% natural fieldstone or quarried stone, hand-sorted and sawn to approximately 1″ thick (¾–1¼” range), and includes matching flats and corners for a full-depth appearance. Stoneyard veneer delivers freeze–thaw durability and decades of low-maintenance service in New England’s variable climate.

Core Product Scope:

- Real natural thin stone veneer, Made in the USA, processed at 2 Spectacle Pond Rd, Littleton, MA.

- Hand-sorted flats and matching corners for continuous full-depth walls.

- Harsh Climate Approved (HCA) and freeze–thaw durable.

- Five shapes: Ledgestone, Ashlar, Square & Rectangular, Mosaic, Round.

- Five New England color blends: Boston Blend®, Colonial Tan, Greenwich Gray, Newport Mist, Vineyard Granite.

Stoneyard veneer demands a mortar that flexes, bonds, and shields each stone through wind, rain, and New England freeze–thaw cycles.

Key Mortar Performance Factors

- Bond Strength: Polymer modifiers adhere to dense natural stone.

- Movement Flexibility: Accommodates thermal shifts and minor settling.

- Moisture Resistance: Defends against freeze–thaw stresses and efflorescence.

A well-chosen mortar extends veneer life for decades with minimal maintenance.

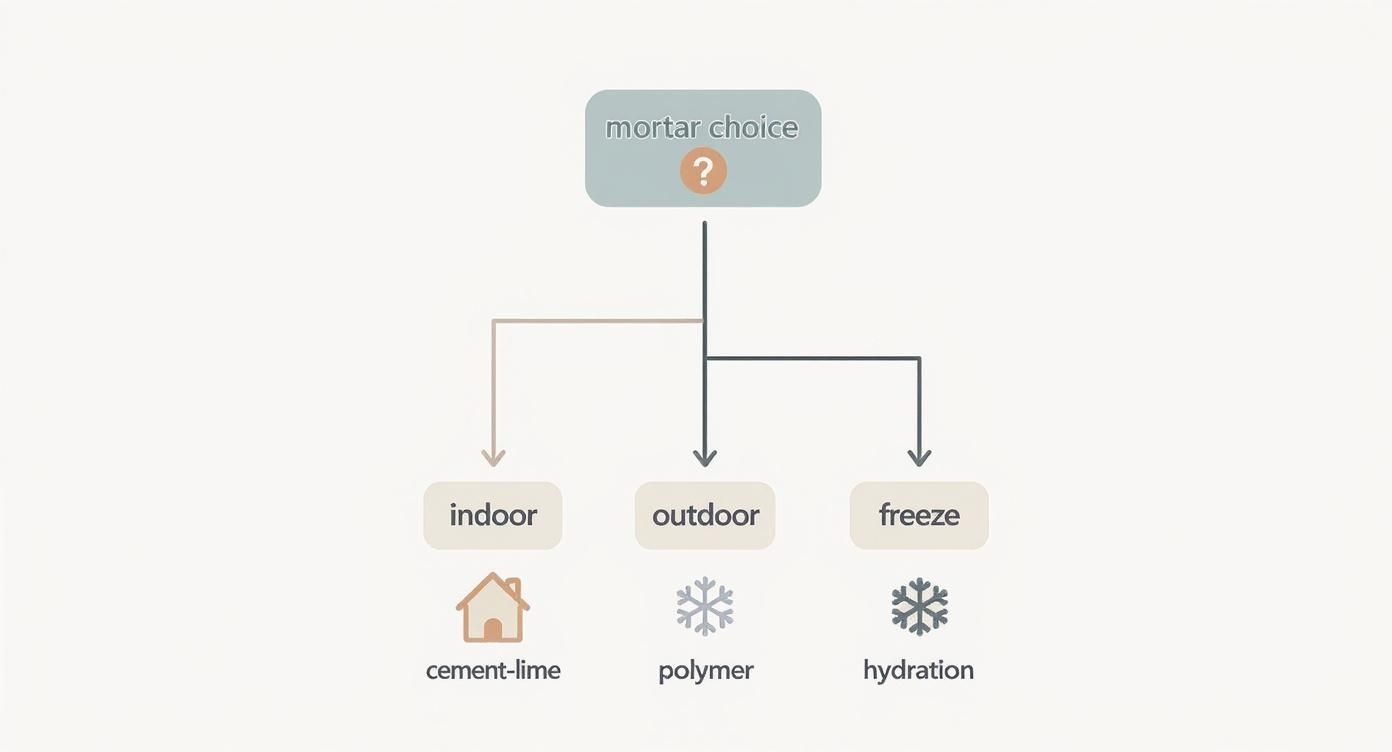

Quick Mortar Selection For Thin Stone Veneer

Pick the right mix by matching mortar properties to your project’s demands:

| Mortar Type | Key Benefit | Ideal Use |

|---|---|---|

| Polymer-Modified Masonry | Strong bond, flexible, freeze–thaw durable | Exterior ledgestone, ashlar walls |

| Cement-Lime Mix | Cost-effective, workable | Interior fireplaces and chimneys |

| Hydration/Membrane System | Integrated moisture barrier | Commercial lobbies, high-rise facades |

In New England’s variable climate, polymer-modified mortars are go-to for outdoor veneer on Boston Blend® Ledgestone or Vineyard Granite Square & Rectangular. Cement-lime blends excel in interior settings with mosaic fireplaces or round cobblestone features. Hydration/membrane systems protect moisture-critical installations like Greenwich Gray Ashlar walls in commercial buildings.

Mortar Basics For Natural Thin Stone Veneer

Mortar is the unsung hero behind a crisp stone veneer installation. Get its recipe right and Stoneyard veneer stands firm through brutal New England freeze–thaw cycles.

- Cement: Provides compressive strength and initiates setting.

- Lime: Improves workability and accommodates minor substrate shifts.

- Sand Gradation: Fills irregular stone back surfaces for maximum adhesion.

- Water-Cement Ratio: Balances cure rate with pore structure for durability.

Specialty additives transform plain mortar into a performance mix. Polymer modifiers add flexibility; water repellents channel moisture; air-entraining agents cushion against frost heave.

A balanced mortar mix supports decades of performance with real stone’s freeze-thaw cycling.

Key Performance Drivers

- Bond Strength: Polymers latch onto dense natural stone surfaces.

- Flexibility: Lime and polymers absorb thermal movement.

- Moisture Management: Water repellents form a microbarrier against rainwater intrusion.

Mixing And Testing

Trial batches help you dial in workability, set time, and consistency:

- 3%–5% polymer admixture by mortar weight for reliable adhesion.

- Water added slowly until a firm ribbon forms when lifting the trowel.

| Parameter | Target Value |

|---|---|

| Water-Cement Ratio | 0.4–0.6 |

| Compressive Strength | ≥ 1,800 psi (Type S) |

| Air Content | 5%–8% |

Matching these targets to HCA Stoneyard veneer ensures decades of service in freeze–thaw environments.

Key Takeaways

- Balance cement, lime, and sand gradation for optimal bond and flexibility.

- Use polymer-modified mixes for outdoor applications; cement-lime for interiors.

- Trial-mix on a scrap board before full-scale work.

- Aim for 0.4–0.6 water-cement ratio and 5%–8% air content.

Comparing Mortar Types For Thin Stone Veneer

Standard Portland cement mortar offers moderate adhesion for indoor veneer but limited flexibility in freeze–thaw conditions.

Polymer-Modified Mortars

Polymer-modified mortar is the weather-ready choice for Boston Blend® and Vineyard Granite veneers. Resins boost flexibility by up to 60% and deliver bond strengths exceeding 1,800 psi.

- Pros:

• Exceptional bond and crack resistance

• Freeze–thaw durability

• Similar cure times to Portland mixes - Cons:

• 20%–30% higher cost

• Requires precise mixing

Over 73% of North American thin stone veneer installs specify polymer-modified mortar.

Hydration Membrane Systems

For moisture-critical settings—Greenwich Gray Ashlar in lobbies or Newport Mist facades—hydration membrane systems integrate a moisture barrier within the mortar bed.

- Protects against water infiltration

- Meets stringent code requirements

- Higher cost justified by long-term performance

Mortar Type Comparison

| Mortar Type | Adhesion Strength | Flexibility | Freeze-Thaw Resistance | Cost Level |

|---|---|---|---|---|

| Portland Cement | Moderate | Low | Moderate | Low |

| Polymer-Modified | High | High | High | Medium-High |

| Hydration Membrane System | High | Medium | Very High | High |

Global research shows the stone veneer market reached USD 2.45 billion in 2024, with a 4.1% CAGR through 2030. Specifying the right mortar maximizes durability and ROI. For adhesive pairings, see our full guide on best adhesive for stone veneer.

Choosing Mortar For Different Stone Shapes

Picking mortar for Stoneyard’s five signature shapes depends on environment, substrate, and freeze–thaw demands.

Selecting Mortar By Shape

- Ledgestone & Ashlar: Linear profiles benefit from polymer-modified mortar for flexibility and bond on tight horizontal joints.

- Square & Rectangular: Uniform blocks on colonial and civic facades perform with polymer blends for a rock-solid bond.

- Mosaic: Irregular indoor fireplaces and chimneys pair with cement-lime mortar enriched with air-entrainment.

- Round: Cobblestone-style exteriors and heritage restorations rely on polymer-modified mixes to handle moisture swings.

A mortar’s flexibility is as critical as bond strength. Match them well for decades of performance.

Matching Mortar To Color Blend

- Boston Blend® Ledgestone: Polymer-modified mortar with water-repellent additives for coastal exteriors.

- Colonial Tan Mosaic: Cement-lime mix with air-entrainment for interior accents and fireplaces.

- Greenwich Gray Ashlar: Hydration membrane mortar in commercial lobbies for moisture control.

- Newport Mist Square & Rectangular: Polymer-modified Type S for modern facades with clean, tight joints.

- Vineyard Granite Round: Flexible polymer blends with freeze–thaw resistance for lake-house foundations and restorations.

Considering Substrate And Climate

- Framed walls: Secure metal lath, scratch coat, clean and dampen before mortaring.

- Masonry/concrete: Remove debris, lightly mist the surface for better suction.

- In freeze-prone zones, always use HCA-rated mortar mixes.

Asia-Pacific forecasts predict 7.2% CAGR in stone veneer mortar adoption from 2025–2033, with polymer-modified blends growing 20% in five years. Discover more insights about the Asia-Pacific stone veneer mortar market

Key Installation Tips

- Maintain a 3/8″–1/2″ mortar bed for optimal adhesion.

- Use corner pieces for continuous full-depth profiles.

- Select mixes rated for freeze–thaw resistance in all New England installations.

Best Practices For Mortar Application With Stoneyard Veneer

A correct mortar bed is the foundation of a durable thin stone veneer installation.

Substrate Preparation

- Secure metal lath on framed walls; apply a firm scratch coat.

- Clean masonry or concrete; remove dust, oil, and debris; mist before work.

Mixing And Bed Thickness

- Mix polymer-modified or Type S mortar per manufacturer’s instructions.

- Aim for a thick, trowel-friendly paste that holds shape.

- Verify workability on a scrap board.

| Thickness | Trowel Angle |

|---|---|

| 3/8″ | 45° |

| 1/2″ | 60° |

Application Techniques

- Spread mortar evenly at the correct trowel angle.

- Press each veneer piece firmly with tight but uniform joints.

- Tool joints after initial set for compressed, sealed edges.

- Protect fresh work from wind and sun to prevent premature drying.

Curing And Protection

- Cover new mortar with damp burlap overnight.

- Maintain ambient temps above 40°F until set.

- Prevent efflorescence by controlling moisture and temperature.

- Use corner pieces to preserve full-depth look at edges.

For step-by-step instructions, see our Complete Stone Veneer Installation Guide and review construction quality control checklists.

Case Examples And Manufactured Veneer Comparison

Example 1: Boston Blend® Ledgestone on a New Hampshire farmhouse uses polymer-modified mortar for long-term freeze–thaw resistance.

Example 2: Greenwich Gray Ashlar in a university lobby employs hydration membrane mortar to channel moisture away from the veneer.

Example 3: Colonial Tan Mosaic fireplace uses a cement-lime mix with air-entrainment for balanced workability and heat-cycle durability.

Natural Veneer Vs Manufactured Brands

- Stoneyard natural veneer: real stone density, full-bodied color, evolving patina, multi-decade freeze–thaw reliability.

- Eldorado Stone (https://eldoradostone.com), Coronado Stone (https://coronado.com), Cultured Stone (https://www.culturedstone.com): cement-based cast veneers prone to water absorption, fading, cracking, and delamination.

Real natural stone retains color and strength through countless freeze–thaw cycles.

For related renovation work, see professional bathroom renovation services.

FAQ On Best Mortar For Stone Veneer

Which mortar for exterior ledgestone or ashlar?

Polymer-modified Type S delivers grip and flexibility for freeze–thaw climates.

What interior mortar for mosaic fireplaces?

Cement-lime mixes with air-entrainment handle heat cycles without spalling.

How long to cure before exposure?

Allow 24–48 hours before rain or hard freeze.

Real stone veneer vs. manufactured adhesives?

Real stone sits on a full mortar bed; faux veneers often rely on thin adhesives that struggle with moisture.

Proper mortar selection extends veneer life by decades under harsh climate cycles.

Troubleshooting common mistakes:

- Skipping trial mixes leads to inconsistent workability.

- Mortar beds under 3/8″ risk weak adhesion.

- Not dampening substrate reduces bond strength.

Curious about sealing? Learn about stone veneer protection in sealer for stone veneer maintenance.

Explore the full Stoneyard Thin Stone Veneer Collection — real New England stone, made in the USA.

Order free samples at https://stoneyard.com/stone-samples/ or schedule a virtual showroom visit at https://stoneyard.com/contact/.

Stoneyard, Inc. https://stoneyard.com