An In-Depth Look at Faux and Natural Stone Veneer

At Stoneyard.com, we have a deep appreciation for the beauty and versatility of stone veneers. We understand that our customers often question the differences between faux stone veneer and natural stone veneer, especially in terms of their production processes. This article aims to provide a detailed comparison of the manufacturing processes of both types of stone veneers.

Faux Stone Veneer: A Testament to Human Innovation

Faux stone veneer, also known as manufactured stone veneer, is a marvel of human ingenuity. It’s designed to replicate the aesthetic appeal of natural stone while being more cost-effective and lightweight. The process begins with a mold created from natural stone. This mold is carefully designed to capture the unique textures and intricate details of the stone, ensuring the faux stone veneer bears an authentic appearance.

The next step involves the preparation of a special mixture. This mixture is composed of cement, lightweight natural aggregates, and iron-oxide pigments. The cement and aggregates provide the structure and durability, while the iron-oxide pigments add the color. This allows for a wide variety of hues, making faux stone veneer a versatile choice for any design.

Once the mixture is prepared, it is poured into the mold and allowed to set. During this time, the mixture hardens and takes on the shape and texture of the mold. After setting, the faux stone veneer is carefully removed from the mold, revealing a lightweight, durable, and cost-effective alternative to natural stone veneer.

Natural Stone Veneer: A Celebration of Nature’s Artistry

Natural stone veneer, on the other hand, is a celebration of nature’s artistry, refined by human craftsmanship. The process begins with the extraction of large slabs of stone from quarries or the gathering of surface stones from farms. This ensures a wide variety of stone types, colors, and textures, as each quarry and farm has its unique geological composition.

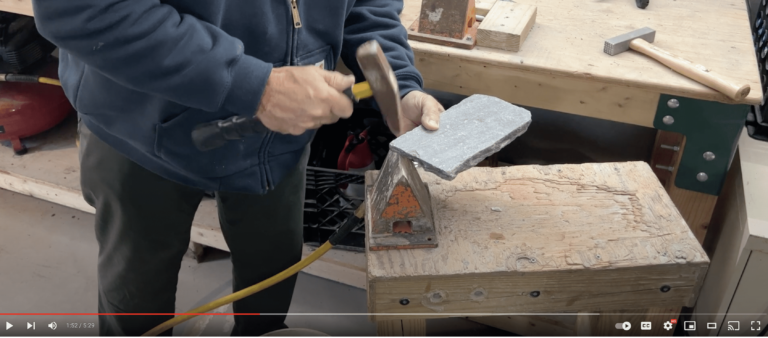

These large slabs of stone are then transported to the processing facility. Here, they are cut into thinner pieces using specialized machinery. This process requires a high degree of precision to ensure the veneer pieces are of uniform thickness while retaining the natural variations that make each piece unique.

The resulting natural stone veneer retains the unique colors and textures of the original stone. Each piece is truly one-of-a-kind, bearing the marks of its geological history. While natural stone veneer is heavier and more expensive than its faux counterpart, it offers unparalleled authenticity and longevity.

Table: A Detailed Comparison of the Manufacturing Processes

| Steps | Faux Stone Veneer | Natural Stone Veneer |

|---|---|---|

| 1 | Creation of mold from natural stone | Stone extraction from quarry or gathering of surface stones from farms |

| 2 | Preparation of cement, aggregate, and pigment mixture | Transport of stone to processing facility |

| 3 | Pouring of mixture into mold | Splitting and Cutting of stone into veneer |

| 4 | Setting and curing of mixture | Quality inspection and packaging |

| 5 | Final product: lightweight and cost-effective veneer | Final product: authentic and durable veneer |

Both faux and natural stone veneers have their unique manufacturing processes, each with its own advantages. At Stoneyard.com, we are proud to offer our customers a variety of natural stone veneers, crafted with care and precision to bring the beauty of nature to your projects.