Outdoor Fireplace Stone Kits

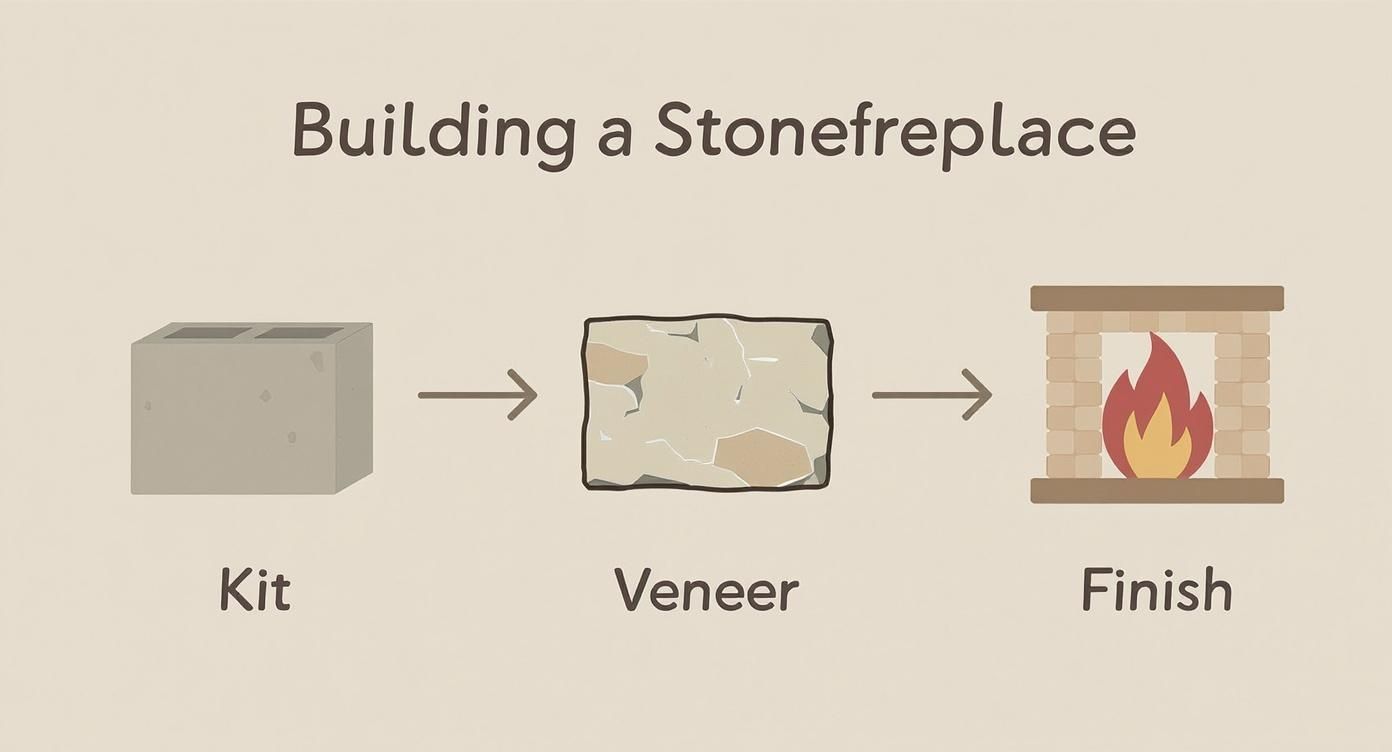

Outdoor fireplace kits finished with real New England natural thin stone veneer offer the structural efficiency of a pre-built core with the authentic appearance of full-thickness stone. This approach combines modern building methods with the performance of authentic, quarried and field-gathered stone crafted at Stoneyard’s facility in Littleton, Massachusetts. The result is a durable outdoor feature with the timeless character of real masonry, avoiding the weight and complexity of traditional full-bed stone construction. Learn more about the https://stoneyard.com/product-category/veneer/thin-stone-veneer/.

Why Real Stone is the Only Choice for Outdoor Fireplace Kits

The material selected to finish an outdoor fireplace kit directly impacts its longevity and appearance. While manufactured options exist, finishing a pre-built structure with real New England thin stone veneer from Stoneyard delivers a level of authenticity and performance that manmade alternatives cannot match.

Every piece of Stoneyard thin veneer is 100% natural stone, sourced from New England and crafted at our Littleton, MA facility. Each piece is hand-sorted and sawn to approximately one inch thick (¾–1¼ inch range), making it ideal for application over common fireplace kit structures, including:

- Concrete masonry units (CMU) or block

- Poured concrete forms

- Metal framing with appropriate sheathing and lath

This system achieves the unmistakable appearance of a solid, full-depth stone fireplace at a fraction of the weight, reducing the load on the foundation.

Built to Last in Harsh Climates

Unlike cement-based products from competitors like Eldorado Stone or Cultured Stone, real natural stone has color and texture throughout its entire body. It will not fade from UV exposure or delaminate after repeated freeze-thaw cycles.

Every Stoneyard product is Harsh Climate Approved (HCA), confirming its suitability for the demanding weather conditions of New England and beyond. Natural New England stone veneer delivers multi-decade performance with minimal maintenance and no color fading.

This inherent durability is essential for exterior applications. The market for authentic, long-lasting building materials continues to expand as property owners invest in permanent, high-value additions. The demand for real stone is driven by its proven ability to withstand extreme weather.

When choosing between real stone and a manufactured substitute for an outdoor fireplace, the long-term performance differences are clear.

Real Stone Veneer vs Manufactured Stone for Outdoor Fireplaces

| Attribute | Stoneyard Natural Thin Stone Veneer | Manufactured Stone (Cement-Based) |

|---|---|---|

| Material Composition | 100% quarried or field-gathered natural stone, sawn thin. | Concrete, aggregates, and artificial color pigments poured into molds. |

| Color Durability | Color is inherent throughout the stone; will not fade from UV exposure. | Surface-level pigments fade and discolor over time in direct sunlight. |

| Freeze-Thaw Resistance | Extremely low water absorption; highly resistant to cracking and spalling. | Porous concrete absorbs water, leading to chipping, cracking, and delamination. |

| Long-Term Appearance | Ages naturally, developing a beautiful patina over decades. | Can chip to reveal the gray concrete underneath; looks worn and artificial over time. |

| Authenticity | Each piece is unique; no repeating patterns. The genuine look and feel of solid stone. | Repetitive patterns are common due to the use of molds. Lacks natural variation. |

| Maintenance | Minimal cleaning required; built to last a lifetime. | May require sealing and is susceptible to damage that is difficult to repair convincingly. |

Ultimately, the choice comes down to lasting value versus a short-term imitation.

The Unmatched Value of Authenticity

Manufactured stone is a concrete product tinted with pigments to imitate real stone. Over time, those pigments fade, and the concrete body can absorb water, leading to surface cracking and deterioration.

Stoneyard’s real stone veneer, sourced and fabricated in New England, develops a natural patina, aging gracefully without losing its structural integrity or color. This commitment to genuine materials ensures your outdoor fireplace becomes a permanent, valuable part of your property. For more on these advantages, see https://stoneyard.com/why-natural-thin-veneer-stone-is-best-for-exterior-use/.

Applying Thin Veneer to Fireplace Kit Structures

Stoneyard’s authentic New England thin stone veneer is engineered to work efficiently with pre-built outdoor fireplace kits, delivering the appearance of a traditional, solid stone fireplace with the speed of a kit build. A lasting installation depends on correct surface preparation and adherence to proven masonry techniques. Whether the kit is made of block, concrete, or metal framing, the application process is designed to create a permanent bond.

This process transforms a basic structural kit into a feature with the look and performance of a full-depth stone fireplace.

The kit provides the form, but our real stone veneer delivers the lasting character and durability. See our installation overview at https://stoneyard.com/installing-stone-veneer/.

Preparing the Substrate for Natural Stone

For a masonry base like concrete block (CMU) or poured concrete, the surface must be clean and unsealed. Any contaminants that could interfere with mortar adhesion—dirt, dust, paint, or sealant—must be removed. Painted or sealed surfaces require sandblasting or grinding to expose a fresh, porous substrate for a secure bond.

Metal-framed kits must be sheathed with a code-compliant material like cement board, followed by a weather-resistant barrier. This provides a solid, stable backing for the stone.

For all substrates, a metal lath is fastened to the structure. This metal grid acts as the key for the mortar and stone.

The foundation for the stone is the scratch coat. A polymer-modified mortar is applied over the lath to a thickness of approximately ½ to ¾ inch. Once cured, this layer creates a solid, uniform surface, ensuring a tenacious, long-lasting bond for the thin stone veneer.

Achieving a Full-Bed Stone Appearance

The full-depth stone appearance is achieved using matching corners. Every Stoneyard thin veneer product includes corresponding 90-degree corner stones cut from the same real stone.

These pieces wrap the outside corners of the fireplace, concealing the underlying structure and creating the visual weight of traditional masonry. By interlocking these corners with the flat veneer pieces, all visible seams are eliminated for a professional, craftsman-quality finish.

Although the veneer is lightweight—around 15 lbs per square foot—the complete system is engineered for heavy-duty, long-term performance. For a comprehensive overview, review https://stoneyard.com/your-guide-to-thin-stone-veneer-installation/.

Key Technical Details for Outdoor Installations

A durable outdoor fireplace, particularly in a region with harsh weather like New England, requires careful attention to installation details. While Stoneyard natural stone veneer is exceptionally durable, the entire installation system—including mortar selection, drainage, and weather-resistant methods—ensures decades of performance without water damage. Find out more at https://stoneyard.com/project/how-to-add-thin-veneer-to-a-fireplace/.

All Stoneyard thin veneer is Harsh Climate Approved (HCA). This designation confirms the stone has extremely low water absorption and can withstand repeated freeze-thaw cycles without cracking or spalling. This natural density distinguishes it from manufactured concrete products, which can absorb moisture and fail over time.

Mortar Selection and Water Management

A permanent bond between the stone and the fireplace structure requires the correct mortar. For outdoor projects, a high-quality, polymer-modified Type S or Type N mortar is necessary. These blends provide the bond strength and flexibility to accommodate temperature-related expansion and contraction.

Water management is equally critical. The installation must include a system to drain any moisture that penetrates behind the veneer. This is a non-negotiable step to keep the fireplace structure dry and prevent long-term damage.

Each layer contributes to the final performance and appearance of the fireplace.

A core component for proper drainage is the weep screed, a metal flashing installed at the base of the veneer wall. It creates a small gap that allows trapped moisture to escape, preventing damage from freezing and expansion.

Flashing and System Integration

Proper flashing is essential for any outdoor stone project. Flashing is required where the fireplace meets another material, such as a patio or an adjacent wall, and at the chimney cap. These metal or membrane strips direct water away from vulnerable joints, preventing it from seeping behind the stone. Our guide at https://stoneyard.com/stone-veneer-flashing-details/ covers this topic in depth.

For gas-fueled fireplaces, proper utility integration is critical. Planning for gas lines must be done correctly and safely from the start. Learn how to install natural gas lines safely and correctly as part of the initial planning. Integrating utilities must be coordinated with the masonry work to ensure all components are safe, code-compliant, and functional.

By focusing on these technical details, your outdoor fireplace kit becomes a permanent, high-performance architectural feature built to withstand the elements.

Choosing the Right Stone Shape and Color Blend

Selecting the appropriate stone for an outdoor fireplace kit involves matching the material’s character to the property’s architectural style. Stoneyard’s authentic New England thin stone veneer, sourced from local quarries and fields, provides a range of shapes and color blends to suit any design. See all the options.

The stone shape defines the fireplace’s texture and overall aesthetic. Whether the goal is the clean, linear look of Ledgestone or the classic, weathered profile of Round stone, each shape creates a distinct feel for the outdoor living space.

Aligning Stone Shape with Architectural Style

Each stone shape is crafted at our Littleton, MA facility to achieve a specific visual result, from rustic and natural to clean and contemporary.

Stoneyard Stone Shapes for Outdoor Fireplaces

| Stone Shape | Description | Common Application |

|---|---|---|

| Ledgestone & Ashlar | Creates clean, stacked lines. Ledgestone is thin and textured, while Ashlar features taller courses for a larger-scale appearance. | Perfect for modern residential patios or sleek commercial outdoor lounges where a structured feel is desired. |

| Square & Rectangular | A classic, organized pattern that delivers a formal and traditional appearance. | An excellent choice for properties with colonial-style architecture or for creating distinguished gathering areas. |

| Mosaic | Irregular, angular pieces that mimic the look of traditional, hand-laid New England fieldstone. | Ideal for rustic fireplaces and chimneys that need to blend seamlessly into a natural landscape. |

| Round | Weathered, glacial stones that evoke historic farmhouse foundations and cobblestone walls. | Suited for lake homes, farmhouse-style properties, and projects aiming for an authentic, heritage appearance. |

The chosen shape sets the architectural tone. Ledgestone and Ashlar offer a contemporary edge, while Mosaic and Round styles feel timeless and connected to the regional landscape.

Selecting the Right New England Color Blend

Once the shape is determined, the color blend establishes the mood. Our five distinct color collections are blended from 100% real stone. The color is inherent to the material, running completely through each piece, ensuring it will never fade.

An outdoor fireplace clad in Boston Blend® Ledgestone offers a versatile mix of gray, tan, and brown tones that complements rustic patios. For a modern outdoor kitchen, the neutral tones of Greenwich Gray Ashlar provide a clean, contemporary aesthetic.

Pairing the right shape with the ideal color blend achieves the desired design outcome. The warm, golden hues of Colonial Tan Mosaic can create a relaxed, coastal atmosphere. For a country club terrace, the rugged gray and pink granite of Vineyard Granite in a Square & Rectangular pattern provides a classic, timeless look.

To see all the possibilities for your project, take a look at the full range of Stoneyard stone veneer colors and shapes.

How to Accurately Plan Your Fireplace Project

A flawless outdoor fireplace installation begins with precise planning. Accurate material takeoffs are essential to avoid project delays from material shortages or the cost of over-ordering.

First, measure the total surface area to be covered with stone. Calculate the square footage for all flat surfaces, subtracting the area of the firebox opening and any other sections that will not receive veneer.

Next, measure the corners separately. Calculate the total linear feet of all outside corners, including the vertical edges of the main structure and chimney, plus any horizontal corners on the hearth or mantel. Corner pieces are sold by the linear foot, and this measurement must be kept separate from the square footage calculation for flats.

Using the Right Tools for Estimation

While manual calculations are possible, a dedicated stone veneer calculator eliminates guesswork and accounts for waste from cutting and fitting.

By entering your square footage for flats and linear footage for corners, the calculator provides the exact quantities to order. You can find the Stoneyard Thin Veneer Material Calculator on our website.

Job Site Logistics and Material Storage

Once the order is placed, plan for delivery and storage. Ensure clear site access for the delivery truck and designate a solid, level area for pallet placement.

Proper material storage is critical:

- Keep Pallets Intact: Leave stone on pallets with protective wrapping until ready for use.

- Protect from Contamination: Store stone away from mud, dirt, or other contaminants that could stain the material or interfere with mortar adhesion.

- Ensure a Stable Base: Place pallets on level, well-drained ground to prevent tipping.

As you plan the build, consider documenting the finished project. Arranging for professional architectural photography for builders can enhance your portfolio and help secure future projects.

From precise measurements to smart job site logistics, proper planning is key to a smooth, professional installation.

Common Questions About Outdoor Fireplace Stone

Here are answers to common questions from builders and homeowners regarding the use of natural thin stone veneer for outdoor fireplace projects.

Can Thin Veneer Be Installed Over an Existing Brick Fireplace?

Yes, Stoneyard natural thin stone veneer can be installed directly over a clean, structurally sound brick surface. The brick must be free of paint, efflorescence, or dirt. Once prepared, a polymer-modified mortar will create a permanent bond.

If the brick is painted or has a deteriorated surface, applying a scratch coat first is the recommended method. This creates a fresh, uniform substrate for the new stone veneer, ensuring a durable, long-lasting bond.

What Is the Real Difference Between Natural and Manufactured Stone Outdoors?

The primary difference is permanence.

Our real New England stone is solid rock with color and structure throughout. It is highly resistant to UV fading and damage from freeze-thaw cycles.

Manufactured stone from brands like Cultured Stone or Eldorado Stone is a concrete product with a surface-applied pigment. As a cement-based material, it is porous and can absorb moisture, leading to cracking, spalling, and color fading. If a piece chips, the gray concrete interior is exposed. Real stone develops a natural patina as it ages.

The authentic New England stone fabricated in Littleton, MA, is Harsh Climate Approved (HCA). Its natural density ensures it withstands weathering without delaminating, providing decades of performance that cement-based products cannot match.

Are Special Footings Required for a Fireplace with Thin Stone Veneer?

Any outdoor fireplace requires a proper concrete footing to support the structure’s weight and resist frost heave. However, the choice of stone significantly impacts the foundation requirements.

- Thin stone veneer weighs approximately 15 lbs per square foot.

- Full-bed stone weighs 50-60 lbs per square foot.

Using thin veneer dramatically reduces the structural load, often allowing for a simpler, less costly foundation while achieving an authentic, solid stone appearance.

How Do I Get Samples for My Outdoor Fireplace Project?

Stoneyard provides free samples to help you select the ideal color and shape for your fireplace kit. Always evaluate samples at the actual project site, as natural light conditions will reveal the stone’s true color and texture.

Explore the full Stoneyard Thin Stone Veneer Collection — real New England stone, made in the USA.

Order free samples at https://stoneyard.com/stone-samples/ or schedule a virtual showroom visit at https://stoneyard.com/contact/.