Best Adhesive for Natural Stone Veneer: A Builder’s Guide

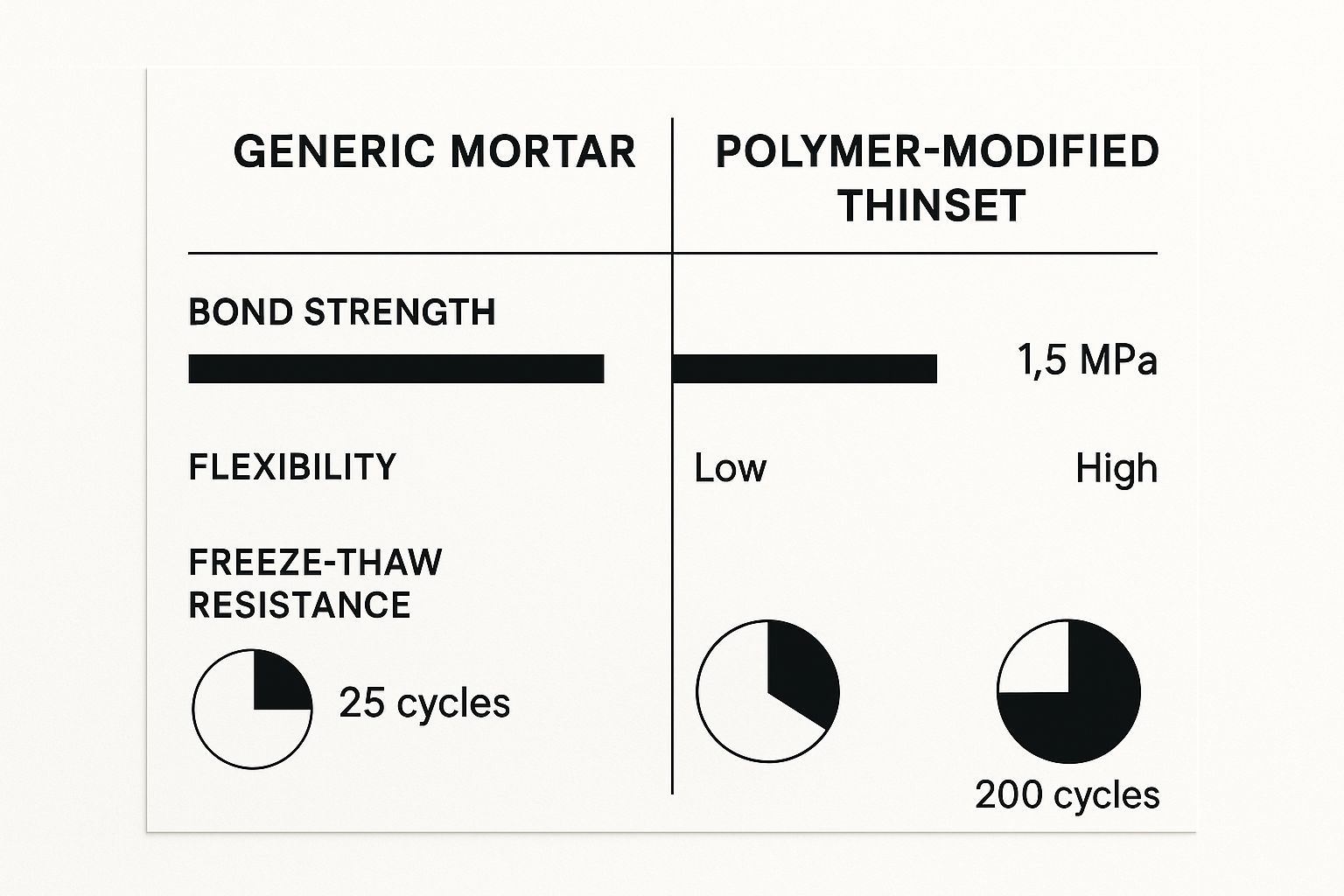

Selecting the best adhesive for natural stone veneer requires understanding that the term “adhesive” refers to a high-performance, polymer-modified thinset mortar system, not generic construction glue or traditional mortar. Standard mortars are not engineered for the demands of vertical stone applications. The success of a residential fireplace clad in Boston Blend® or a commercial facade using Greenwich Gray depends on using a system with superior bond strength, flexibility, and freeze-thaw durability.

For professional-grade installations using real New England stone, the Laticrete Masonry Veneer Installation System (MVIS) is the industry standard. It provides a comprehensive, warrantied solution that ensures long-term performance and avoids the common pitfalls of using improper materials.

What to Look for in a Stone Veneer Adhesive

The term “adhesive” in the context of thin stone veneer refers to an engineered, polymer-modified mortar, not a generic masonry mix. This distinction is critical, as the adhesive system must provide tenacious bond strength to support stone weighing up to 15 pounds per square foot against gravity. It also needs flexibility to accommodate substrate movement and exceptional resistance to the freeze-thaw cycles common in the New England climate.

Key performance factors for a stone veneer adhesive include:

Bond Strength: The mortar must achieve high tensile and shear strength to prevent sagging and delamination.

Flexibility: Polymer modification allows the mortar to absorb minor structural movement and thermal expansion without cracking.

Freeze/Thaw Resistance: A dense, low-porosity structure prevents water intrusion, which can freeze, expand, and dislodge stones.

Water Retention: The ability to retain moisture ensures a slow, complete chemical cure, maximizing the mortar’s final strength.

A product that meets these criteria ensures a durable, low-maintenance installation with a multi-decade lifespan.

Common Mistakes to Avoid

The most critical mistake in stone veneer installation is using the wrong type of mortar. Standard masonry mortars, such as Type N or Type S, must not be used to adhere thin stone veneer. These products are formulated for compressive strength in load-bearing applications (like full-bed brick walls) and lack the adhesive properties and flexibility required for vertical veneer.

Using Type S or Type N mortar for thin stone veneer leads to bond failure. Their rigid composition cannot handle the thermal expansion and contraction of New England weather, causing cracks that allow water intrusion. In winter, this trapped moisture freezes and expands, a process known as frost wedging, which will delaminate the stone from the substrate. Improper mixing or poor substrate preparation will also compromise the bond, leading to costly failures. For a deeper look, see our guide on five common mistakes in thin stone veneer installation.

Best Adhesive Options for Natural Stone Veneer

For natural thin stone veneer with a thickness of ¾”–1¼”, a complete, engineered system provides the most reliable performance.

#1: Laticrete MVIS System

The Laticrete Masonry Veneer Installation System (MVIS) is the industry standard for natural thin stone veneer. It is a comprehensive, single-source system engineered to work together, providing a warrantied installation that eliminates material compatibility issues. This system is specified for demanding residential projects, such as a Colonial Tan chimney on a coastal home, and large-scale commercial applications like university buildings clad in Greenwich Gray.

The core components include:

MVIS Air & Water Barrier: A liquid-applied membrane that creates a seamless waterproof and vapor barrier, protecting the substrate from moisture damage.

MVIS Hi-Bond Veneer Mortar: A polymer-modified adhesive mortar engineered with superior non-sag properties and bond strength that exceeds ANSI A118.15 requirements.

MVIS Pointing Mortar: A chemically compatible mortar that ensures consistent color, strength, and durability in the joints.

Secondary Adhesive Options

While Laticrete MVIS is the recommended system, other high-performance mortars can be suitable if verified for natural stone compatibility.

Ardex X 77 MICROTEC Fiber Reinforced Thin Set Mortar: Known for its high sag resistance and extended open time. Its compatibility must be confirmed for the specific weight and type of natural stone used.

Custom Building Products ProLite Premium Large Format Tile Mortar: A lightweight, non-sag mortar. Its suitability depends on meeting the bond strength requirements for heavier natural stones like Vineyard Granite.

Application Tips for a Permanent Bond

Correct application technique is as critical as material selection. Even the best adhesive for stone veneer will fail without proper installation practices.

First, ensure the substrate is clean, structurally sound, and free of any contaminants like dust, oil, or paint that could act as a bond-breaker. For wood-framed structures, this typically involves a code-compliant system of weather-resistant barrier, metal lath, and a scratch coat.

Second, back-buttering each piece of stone is mandatory. This technique involves applying a thin, consistent layer of mortar to the back of the stone before setting it into the mortar bed on the wall. This achieves 100% coverage, eliminating voids where water could collect and freeze.

Finally, monitor environmental conditions. Most polymer-modified mortars require ambient and surface temperatures to remain between 40°F and 95°F during application and for at least 72 hours afterward to ensure a full and proper cure. Protect fresh work from direct sun, wind, and rain. For detailed steps, review Stoneyard’s guide on adhering the stone.

Frequently Asked Questions

Can you use Type S mortar for stone veneer?

No. Type S mortar is not recommended for adhering thin stone veneer. It lacks the polymer modification required for high bond strength and flexibility, making it prone to failure in vertical, non-load-bearing applications, especially in climates with freeze-thaw cycles.

What’s the strongest stone veneer adhesive?

The strongest and most reliable solution is an engineered system like the Laticrete MVIS. Its strength is not just in its high-bond mortar but in the compatibility of all its components—from the air and water barrier to the pointing mortar—which work together to create a durable, warrantied installation.

Is thinset better than mortar for stone veneer?

Yes, a high-performance, polymer-modified thinset mortar is significantly better than a traditional masonry mortar (like Type N or S) for thin stone veneer on vertical surfaces. These engineered thinsets are specifically formulated with the high bond strength, non-sag properties, and flexibility needed for this application.

Conclusion

The long-term success of any natural stone veneer project is determined by the quality of the adhesive system. Using an engineered, polymer-modified thinset mortar system is not an upgrade—it is a requirement for a permanent, safe, and warrantied installation. For projects using real New England stone veneer, from a residential Newport Mist accent wall to a large commercial facade, always follow manufacturer specifications like those from Stoneyard.com. This ensures the craftsmanship of the installation matches the timeless quality of the stone itself.

Explore the full Stoneyard Thin Stone Veneer Collection, order free samples, or take a virtual showroom visit at Stoneyard.com.