5 Common Mistakes In Thin Stone Veneer Installation

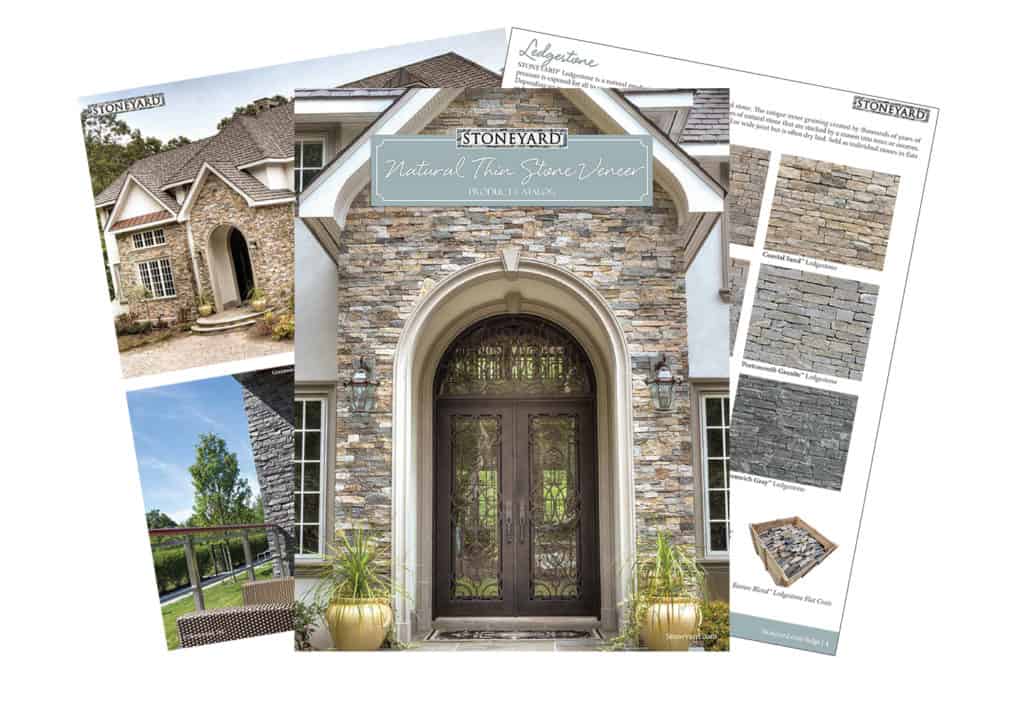

Thin stone veneer adds a touch of nature to any space, but achieving a flawless installation requires careful planning and execution. Unfortunately, several common mistakes can mar the beauty and

Installing Thin Stone Veneer Over Brick

Can you install stone veneer over brick? Can you install thin stone veneer over a brick wall? This is one of our most frequently asked questions by our customers. Good

Your Guide to Thin Stone Veneer Installation

A 5 Step Video Series We’ve created a comprehensive guide to thin stone veneer installation, meticulously designed to assist both professionals in the field and DIY enthusiasts. It provides a

Natural Stone Bathroom Inspiration and Cleaning

Using Stoneyard Natural Thin Stone Veneer Wishing your bathroom can feel like you’re stepping into a spa? Natural stone veneer is the key to transforming that space into a peaceful

Using Laticrete MVIS Air & Water Barrier for the Installation of Stone Veneer

Uncover expert tips for a successful installation of stone veneer using Laticrete Air & Water Barrier.

11 Questions to Ask Your Stonemason About Stone Veneer

11 Questions to Ask a Stonemason, Landscaper, or Contractor About Stone Veneer 11 Questions to Ask A Stone Contractor-230711 1. Can I see photos of your projects? Stonemasons

Detailed Installation Tips

Three Thin Stone Veneer Corner Installation Tips

How to Use Thin Veneer Corners to Elevate your Design There are many benefits to using natural thin cut stone veneer including a wide range of applications, ease of use,

Three Mortar Joint Options for the Perfect Installation

https://youtu.be/vwXY1SjRz50 This video shows examples of the different ways to install and grout natural thin stone veneer choosing grout color, size, offset and even overgrouting. David Croteau of Stoneyard.com explains

Corners for Natural Thin Stone Veneer

Available to Match All Colors and Shapes Thin Veneer is 1 inch thick, and light enough to adhere directly to any masonry surface. Once installed, it is nearly impossible to